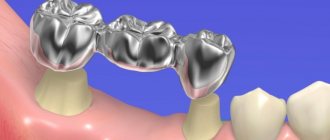

A combined crown is a structure consisting of a metal base and a shell. A composite composition, plastic or ceramics is used as an external coating. The color and texture of the shell is matched to the parameters of natural dental elements. The frame is made of stainless steel or alloys of cobalt and chromium, nickel and chromium. The crown is made using stamping or casting. The thickness of stamped dentures is from 0.3 mm. For cast bases, the thickness reaches 0.4-0.5 mm. Frames of the low price segment are created from dental sockets made of stainless steel. A standard sleeve is taken, broached and forged on a die created from an impression from the problem tooth. When making a cast base, an impression is taken from the dental element and a wax model is made. The internal diameter of the correct frame should exceed the diameter of the tooth stump by 50-100 microns. This guarantees the strength of the connection between the microprosthesis and the element. Cast structures have the specified accuracy. Bases for ceramic or composite cladding are made using standard technology. Today, adhesive liquids are used to create a strong bond between the metal substrate and the plastic. The thickness of the surface layer depends on the material and location on the crown (in the cervical, cutting or central part). To prevent the base from showing through the ceramic layer, white varnish or yellow titanium nitride is applied on top. The popularity of prostheses made of gold alloys is due to biocompatibility and lack of translucency. The veneer performs an aesthetic function and is applied to the vestibular surface.

Metal and plastic

These are inexpensive crowns that have been placed on the front teeth for decades.

The metal base was covered with an inert synthetic. But time has shown the conventional aesthetics of the structures - over time, the coating darkened and the metal became visible. After a couple of years, a painful replacement of the prosthesis was required. Today, metal-plastic crowns are cheap and can be used for the restoration of molars. But their aesthetic life is maximum 3 years. Therefore, this option is recommended as temporary. Before permanent prosthetics during implantation or in other cases when it is impossible to install a permanent prosthesis immediately after treatment.

Price issue

The cost is determined mainly by the cladding material (not counting products made of precious metals). Depending on it, the price of microprosthetics can range from several to 2 tens of thousand rubles.

The table shows approximate prices for lined structures. But you need to understand that if you want, you can always find an option a couple of thousand cheaper than the market average.

| Type of crown | Cost, rub. | Features of the instructions |

| Metal-plastic | From 2 500 | Frame made of dental socket (stainless steel) |

| Metal composite | From 7 000 | Material GC Gradia or TwiNY |

| Metal-ceramic | From 8 000 | Nickel-chrome alloy frame |

| Metal-ceramic | From 18 000 | Gold frame |

Zirconium dioxide and ceramics

Such dentures are flawless and are recommended for installation on the front teeth. The units are stronger than natural ones due to the stable zirconium frame, and the ceramic coating gives them a visual naturalness, ensuring correct light reflection.

But such a tooth crown is expensive. And it’s not always justified. Modern solid ceramics are close in strength to natural enamel. Therefore, in most cases, frameless ceramics, which are indistinguishable from natural units, are chosen for the restoration of the beauty area.

In addition, Cerec porcelain crowns for front teeth can be made within 1.5 hours; the price of this option is more affordable and its aesthetics are high. The artificial units created using innovative equipment will be flawless, you don’t need to get used to them - their parameters are calculated by a computer program taking into account the anatomical characteristics of a particular patient.

Reviews

Today, the combined crown can be called “folk” due to its popularity. The time of fashion for gold “fixes” is irrevocably passed.

The main question that worries patients is how long can crowns lined with various materials last? If you have your own experience in this regard, please share it with visitors to our site. The comment form is at the bottom of the page.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags dental crowns fixed dentures

Did you like the article? stay tuned

Previous article

Teeth analogues from the Japanese company Yamahachi are the best solution for removable prosthetics

Next article

Relevance of neuromuscular dentistry

Metal ceramics

If it is necessary to replace molars, ceramics will not be suitable; the material is too fragile and will not withstand the increased load. Therefore, it is more reasonable to install metal-ceramic or zirconium crowns on chewing teeth. The last segment is more expensive. Therefore, many patients choose a metal cast crown coated with ceramics.

Modern frames are made only by casting. This ensures a tight fit of the crown in the remains of the natural tooth, preventing the entry of pathogenic microflora into the tooth.

Materials

Stamped crowns are made from 900 gold or special stainless steel (grade 1x18N9T), which is easy to melt and forge. If the factory stamped sleeve is made of gold, then, due to the softness of this variety, the cutting edge is soldered from a metal of a different standard - harder 750.

But usually gold crowns are no longer placed. And yellow metal crowns, manufactured in modern dental prosthetic workshops, are made by sputtering titanium nitride onto steel blanks, imitating 900 gold.

In addition to steel and gold, blanks made of platinum, an alloy of cobalt and chromium, silver-palladium and titanium can be used.

When are combined crowns installed?

Metal-ceramics can be installed if a large tooth crown is destroyed; the frame will protect the remains of the molars from excessive loads.

Metal ceramics are installed:

- For a real tooth with a healthy, strong root that has crumbled by 50% or more.

- As part of the bridge structure - crowns on the supporting teeth.

- As a final prosthesis on implants.

The option is quite worthy for maintaining the function of chewing teeth and helping to preserve the structure of periodontal tissues.

But in general, if a tooth is more than 50 percent damaged, it is more advisable to install a Cerec module, and the tooth restored in this way will serve you for many more years.

Indications and contraindications

Installation of combined products is indicated in the following cases:

- the crown part of the tooth is severely damaged and cannot be restored by other methods (approximately two-thirds of the tissue must be removed);

- increased abrasion, the lower third of the face is characterized by a decrease in height, that is, the normal contours are distorted;

- the color of the enamel has been changed, the process is irreversible and other restoration options will not be effective;

- mobility of individual units of the row is observed (such crowns are used as splinting, strengthening devices);

- partial edentia, in which the use of bridge structures is recommended;

- for implantation;

- as a reliable support for fixing orthodontic appliances;

- when replacing old dentures that are damaged or worn out.

Combined products are not installed in the following situations:

- the wall of a natural tooth is thinned, weakened and will not withstand additional load;

- risks of serious pulp damage during turning;

- the need to restore lower anterior teeth;

- deep bite, accompanied by protrusion of the upper incisors;

- age restrictions (such systems are not used until 16-18 years old);

- bruxism.

Advantages

Due to the metal base, combined crowns are stronger than real teeth. With proper care, their service life is 15 years

.

Additional advantages:

- They do not lose their shape or shade.

- Visually close to natural enamel. Therefore, they are invisible against the background of neighboring molars when laughing or talking.

- Reliable protection and functionality - you can safely chew your usual food.

- The risk of allergies is minimal (traditionally, up to 2% of people are sensitive to alloys).

When installed correctly, it adheres to the gum and tooth, protecting the units

Life time

The service life of veneered products is determined by several factors, including the type of lining material, the professionalism of the doctor, the accuracy of technology, and care of the oral cavity after prosthetics.

The approximate service life of combined models, depending on the type of cladding, is:

- for metal ceramics – 10-15 years;

- for metal composite products – from 5 to 15 years, depending on the grade (brand) of the composite;

- for metal-plastic structures – up to 5 years.

Failure can occur for various reasons. If for metal-plastic products the main danger is the separation of plastic from the metal, then for composite and ceramic products it is cracks and chips.

While composite products can be repaired in the patient's mouth, with metal ceramics there is no other way to correct the problem other than replacing the crown. The same can be said about metal-plastic microprostheses. Detachment of the lining will inevitably lead to food getting underneath and rotting. Therefore, the sooner the prosthesis is replaced, the better.

Manufacturing and installation of combined crowns

To put a metal-ceramic crown on your teeth (cost – 17,900 rubles / tooth), it will take 7-14 days

.

Manufacturing sequence:

- The tooth is prepared to the thickness of the crown.

- An impression is taken from which a cast crown is made.

- It is advisable to install temporary plastic protection on treated teeth.

- A metal frame is made and tried on.

- If adjustments are needed, they are made, and another fitting follows. When the artificial tooth fits, the metal is coated with ceramic.

- During installation, the tooth is covered with a protective compound, and the prosthesis is fixed with dental cement.

A nuance: the ceramics are applied in layers, each layer is baked in an oven under high temperature. Therefore, the coating is stable and securely attached to the metal base. Contact me at the dentist and we will decide what crown to put on the tooth in your case.

Multimedia presentation on PM 02 “Technology for the manufacture of fixed dentures”

Crowns according to Belkin

Crown according to Belkin

It is a stamped crown, the vestibular surface of which is lined with plastic.

But before prosthetics, you need to know the indications for the use of a combined crown according to Belkin

Yes Yes…

1. Defects of the coronal part of the incisors and premolars of the upper jaw of carious and non-carious origin. 2. Anomalies in the shape, size, position of the upper jaw incisors. 3. Defects in the dentition of the upper jaw, as supporting elements in bridges. 4. For splinting in case of periodontal diseases

Disadvantages of the combined crown according to Belkin

Where would we be without them...

Only in the first time after strengthening combined artificial crowns according to Belkin

match the color of natural teeth. Often the underlying metal frame is exposed or visible. Due to the difference in thermal expansion coefficients, as well as the purely mechanical method of joining plastic and metal, oral fluid along with food debris penetrates into the small cracks formed at the junction. The resulting processes of fermentation and decay contribute to even greater separation of dissimilar materials, change the color of the veneer and can lead to the destruction of the hard tissues of the stump of a natural tooth. The plastic, being in contact with the fluid of the gingival groove, swells and begins to put pressure on the underlying gingival margin, local gingivitis occurs with corresponding symptoms (unpleasant odor, discoloration of the gums, swelling, pain on palpation), and the swollen plastic contributes to the decementation of the crown. Crowns do not have sufficient strength, and their manufacture requires grinding off a much larger layer of hard tissue on the vestibular side than when using ordinary stamped crowns. In addition, a weakened metal structure turns out to be of little use for supporting a bridge.

Clinical and laboratory stages of manufacturing a combined crown according to Belkin

1. Clinical. Tooth preparation. Taking working and auxiliary impressions.

1. Laboratory. Manufacturing a conventional stamped metal crown.

2. Clinical. Fitting a stamped metal crown into the oral cavity.

Taking an impression.

2. Laboratory. Making a combined crown according to Belkin

.

3. Clinical. Fitting an artificial crown in the oral cavity.

3. Laboratory. Crown polishing.

4. Clinical. Fixation of the combined crown with cement.

Yes, you're damn right!

r Hey, pssssssssssssssssssssssssssssssssss] You probably want to know how

is this done in more detail?

1st clinical stage.

The abutment tooth is prepared under a full metal crown, impressions are taken from both jaws with alginate, silicone, polysulfide, and polyester masses. A provisional crown is made on the prepared tooth.

1st laboratory stage.

Using conventional technology, a stamped crown is made.

2nd clinical stage.

Fitting an artificial crown in the oral cavity. The supporting tooth is additionally ground from the cutting, vestibular and contact surfaces to the thickness of the plastic lining (1.0-1.5 mm). A hole is drilled on the vestibular surface of the crown, the crown is filled with softened wax and placed on the abutment tooth. Inside the crown, an imprint of the prepared tooth stump is obtained. The remaining layer of wax corresponds to the thickness of the hard tissues sanded off to make the veneer. Excess wax is squeezed out of the crown after it is placed. Without removing the crown, we get an impression of the entire dentition. After the impression is made, a crown is inserted into it. Based on the existing natural teeth, in daylight the corresponding color of the plastic is selected using the coloring.

2nd laboratory stage

. Plaster casting of a working model. The crown is gently heated over a flame to melt the existing wax and remove the crown. The remaining wax is removed, the crown is bleached and polished. The vestibular wall of the crown is cut out with a carborundum disk or a wheel-shaped bur in such a way that its integrity is preserved in the cervical part to a width of 0.5-1 mm (the area extending into the gingival groove) and the cutting edge. To strengthen the plastic, the edges are cut with a vulcanite disk or a wheel-shaped bur, and cuts (retention points) are made in the shape of a dovetail.

The prepared frame of the stamped crown is installed on the working model and checked to see if any deformation has occurred. Then the crown is removed from the model, degreased, and the gingival rim and other areas of the crown edge are masked with a special white insulating varnish (EDA type). After heating the crown frame to fix and dry the varnish, it is again installed on the working model and the anatomical shape of the vestibular surface is modeled with wax, taking into account the shape of adjacent teeth.

A plaster block is cut out of the model, including and standing next to the supporting adjacent teeth, the labial surface is plastered into the cuvette, and after an insulating coating with oil or petroleum jelly, the upper part of the cuvette is cast. Open the cuvette, melt the wax with a stream of boiling water and, after cooling, mold plastic of the appropriate color. After polymerization, the crown is removed from the ditch, trimmed, ground, and polished.

3rd clinical stage.

Fitting a combined crown in the oral cavity. The crown must meet all the requirements for full artificial crowns and must satisfy the aesthetic needs of the patient. First of all, the accuracy of the fit of the crown to the tooth stump is checked. Use carbon paper for this. Using spherical and fissure burs, carefully remove areas of plastic stained during the application of the crown, which prevents it from fitting more tightly to the abutment tooth. If the metal frame met all the requirements when applied in the oral cavity, then the finished combined crown may cause a violation of the occlusal relationship due to the breaking off or displacement of the stump of a plaster tooth when molding the plastic dough into a ditch. The occlusal and articulatory relationships of the upper and lower jaws are checked.

5th laboratory stage.

Final polishing of the plastic surface of the crown.

6th clinical stage.

Fixation of the combined crown with cement. Features of fixation: 1.cement is selected in the appropriate color; 2. When pre-treating the crown, avoid the use of organic solvents (alcohol, ether).

And-and-and-and-and-and-and-and-and-and-and remember!

Brush your teeth every two days

Brush your teeth twice a day

Splinting teeth is one of the dental methods of treating and restoring the health of the dentition. by dentists when

Patients

experience pathological looseness

or

mobility of the dentition

or single teeth.

In order to strengthen and preserve your own teeth, and thereby prevent their loss, the method of splinting mobile teeth is used. Splinting teeth is

a method of treating periodontal diseases, making it

possible to avoid tooth loss

in patients with severe forms of periodontitis. Splinting is necessary if the patient has pathological tooth mobility.

Is it possible or not?

Combined type crowns are placed on any teeth. Most often on those located in the smile zone - frontal maxillary, upper premolars. If the client wishes, it is possible to cover the molars, but it will not be advisable to sharpen the supporting teeth too much.

It is recommended to install combined speakers in the following cases:

- destruction of more than 70% of the tooth volume;

- decreased height of the lower part of the face due to tooth wear;

- irreversible change in enamel shade;

- severe tooth mobility;

- complete or partial absence of teeth for various reasons;

- implantation;

- replacing old crowns;

- placing medications in the tooth;

- production of supports for special devices.

"Advantages and disadvantages"

pros

- The first (and often the decisive) plus is accessibility. The cost can only be compared with plastic products. The average cost of manufacturing and installing one crown without coating (a metal prosthesis without cladding) is about 2,000 rubles in Moscow. With spraying - more than 2200. With different types of linings that hide the metal (linings can be plastic or ceramic) - from 2600 to 5,000.

- The thickness of the walls does not exceed 0.3 mm, which means that, taking into account the additional layer of cement, no more than 0.4 mm is removed from the tooth. That is, depulpation is not performed.

- Speed of production and ease of installation.

- Over the century of use of the method, there are literally isolated cases of rejection of installed crowns as a result of incompatibility of tissues with metals.

Minuses

- Unaesthetic - metal in the mouth, even if it is gold, does not correspond to modern concepts of beauty.

- Insufficient strength of the walls, due to which it quickly grinds down and wears out, allowing infection to penetrate inside.

- Galvanosis is possible - the occurrence of a weak electric current as a result of the impact of acids contained in food and saliva on the metal of the crown.

- The functions of the teeth are not fully restored, and this affects the degree of grinding of food when eating it.

- In cases of “sinks” in the cement layer, aggressive media from food will penetrate to the pulp.

- Anatomical features are not taken into account, which results in incomplete adhesion of the surfaces of opposing teeth.

Crown preparation

Since the crown has walls of a maximum of 0.3 mm (this is practically dense steel foil, with the ability to cut it with scissors), a small amount of dental tissue is prepared. The stump is ground to a cylindrical shape; only on the occlusal surface and in the neck area is the relief maintained according to the location of the enamel.

- The surface is treated with diamond wheels of different diameters, removing a layer of 0.5 mm. A difference of 0.2 mm is made for the use of cement under the crown.

- The distance between the prosthetic tooth and its antagonist on the opposite jaw is constantly checked. To do this, a wax strip test is used, on which, after clenching the teeth, an impression appears, from which the doctor is guided as to the need for modifications to the structure.

- The preparation of the proximal surfaces of the tooth is done - that is, those lateral parts that face the neighbors.

- The buccal and palatal area is treated last, giving the stump the shape of a cylinder. This will make it easier to install the prosthesis and fix it more reliably. The cylindrical surface will also make it possible in the future, when it is time to change the crown, to easily remove it without particularly injuring the stump.

- There should not be a large gap when the edge of the crown touches the dental neck. Ideally, its edge should slightly touch the gum or even sink into it, but no more than 0.3 mm. This will not prevent food debris from getting under the crown, but there will still be less of it than if there was a gap.

The need to replace crowns may arise within 2-4 years. Because no matter how carefully the cement layer is applied, sooner or later aggressive environments from food and saliva, microorganisms, and toxins formed in the mouth overnight will begin to penetrate into the space between the tooth stump and the crown.

The cement itself, under the influence of many factors, gradually breaks down, dissolves and is washed out from under the crown. A gap is formed where food particles get clogged. All this begins to gradually destroy the tooth, either causing caries, or demineralizing it, making it fragile.