Prosthetics with solid-cast bridges are now being used more and more often due to the possibility of eliminating a large number of defects using this method. To understand what this restoration option is, let’s consider how the structure is manufactured in a clinical laboratory setting, and what advantages and disadvantages it has.

What are solid bridges?

Manufacturing of a combined solid-cast bridge prosthesis

A bridge is a structure with supporting elements and several artificial crowns that replace missing teeth. The concept of “solid cast” implies that the structure is cast simultaneously.

The manufacture of a one-piece bridge prosthesis eliminates the adhesion of various elements to each other. The structure is made from casting various alloys, and most often it is gold, silver, palladium, chromium, cobalt.

Simultaneous casting of the prosthesis makes it possible to improve its quality in terms of strength and performance of basic functions. They are now valued in dentistry due to their improved manufacturing techniques and relatively low cost, which allows this restoration option to be considered by a large number of patients.

What they look like

A solid cast bridge resembles a bridge. The design consists of several connected crowns, which allows you to replace a defect on one side of the jaw. Two crowns from the prosthesis are supporting; they are fixed to healthy teeth. Externally, the metal frame has a specific color, which affects aesthetics, which is why this restoration option is being considered for replacing the chewing group of teeth.

Important! The main difference between a solid-cast bridge structure is that it is a single whole without joints or soldered elements.

Such products can be improved by combining different manufacturing options, spraying, and coating with a polymer overlay. This method of restoration is considered for the loss of chewing teeth.

This is what a solid-cast bridge prosthesis of chewing teeth looks like.

Bridges can be placed on the front teeth, but their appearance does not even closely match the natural tissues of the tooth, so more aesthetic options are selected to restore the “smile zone.” If the choice was made on a solid-cast bridge structure, then it is possible to cover it with a composite, which will make the appearance more natural.

Types of dental bridges

Bridges come in different types; they are divided into main types depending on the material and method of manufacture, as well as installation. Let's take a closer look at the types of dental bridges.

Metal bridge structures

Recently they are rarely used due to unsatisfactory aesthetic characteristics. However, dental bridges, consisting of all-metal crowns on the supporting teeth and metal artificial teeth between them, are perhaps the strongest and relatively inexpensive. But at the same time, such a dental bridge can cause a number of inconveniences in addition to its unaesthetic appearance: since the structure is quite heavy, the supporting teeth under it can be destroyed, a metallic taste may be present in the mouth, and the soft tissues of the mucous membrane may undergo an allergic reaction.

Metal-ceramic bridges

are considered as durable as metal structures, but at the same time surpass them in aesthetic qualities, since the ceramic lining of a metal-ceramic crown ideally imitates the natural color of tooth enamel and can be matched to the shade of neighboring teeth. At the same time, a metal frame that runs through the entire structure and connects its parts allows the prostheses to be made quite extensive. But at the same time, it shines through the ceramics, which does not look very aesthetically pleasing in the smile area. In order to solve the problem, recently bridges have increasingly been made from zirconium dioxide, a white metal.

Ceramic dental bridges

, or in other words, all-ceramic, are bridge-like structures that do not have a metal frame. They are inferior in strength to a metal-ceramic bridge, but at the same time superior to it in aesthetic qualities, since ceramics have almost the same transparency as natural dental tissue.

Plastic dental bridges

are the most cost-effective orthopedic structures. At the same time, modern dental plastics are absolutely hypoallergenic and can imitate the natural color of enamel and the anatomical shape of dental fissures. However, a plastic bridge is more of a temporary measure, since its service life is relatively short, and its strength is significantly inferior to that of ceramic and metal-ceramic structures. In modern dentistry, dental bridges made of plastic are installed as temporary structures for the period of production of permanent dentures or for a short period in case of limited financial capabilities of the patient.

Metal-plastic bridges

– stronger and more durable structures than plastic ones, which, however, are also inferior in service life to metal-ceramic and all-ceramic prostheses. A dental bridge made of plastic on a metal frame will last on average about two years, the maximum limit does not exceed five years, by which time the plastic crown part of the structure will most likely change its color under the influence of pigments, saliva and the aggressive acid-base environment in the oral cavity.

According to the manufacturing method, bridges are divided into solid, stamped and adhesive. A pressed bridge is made from single crowns and artificial teeth that are soldered together, so another name for this design is a soldered bridge. This production method is becoming a thing of the past, as it is inferior in strength to the casting method, and also combines several dissimilar metals, which can cause discomfort when wearing the structure. Cast bridge structures are much stronger and more convenient. An adhesive bridge is made directly in the patient’s mouth from modern composite materials and requires minimal grinding of the teeth adjacent to the defect. Such a prosthesis does not have supporting crowns; it consists of a fiberglass arch, its ends resting on protrusions drilled in the supporting teeth, and an artificial tooth grown on this arch. Since this design is inferior in strength to bridges with abutment crowns, it can be used to replace only one lost tooth.

Materials used

For the manufacture of solid-cast prostheses, gold (both in pure form and sputtering) and stainless metals, or rather their alloys, are used.

The materials used can be combined, and such a prosthesis will be classified as combined or with veneer. The following materials are used as the base material for the manufacture of a solid-cast bridge:

- gold;

- silver and palladium;

- cobalt and chromium.

Structures made of chromium and cobalt can be improved by manufacturing in their natural form, gold plating, or ceramic coating to resemble natural hard tissues of teeth.

Stages of installing a metal-ceramic crown

Prosthetics are more the work of a dental technician than an orthodontist. The crown will be made in 7-10 days. However, before installation, it is necessary to prepare the patient, carry out appropriate treatment if necessary, and also prepare the tooth. Therefore, you will need to visit the clinic 4-5 times (it is possible to combine several stages in one visit). If problems are discovered, the number of visits to the doctor will increase.

The presence of a pain symptom during installation of a prosthesis depends on the tooth:

- on the pulpless one the pain is not felt. However, if you ask for additional anesthesia, they will give it;

- on “living” teeth, with the root preserved, there is an unpleasant sensation, pain is felt during grinding. Anesthesia solves the problem, but it is advisable to do a test to avoid an allergic reaction.

When installing dental crowns, when a temporary prosthesis is installed, the edge of the gum may be damaged and discomfort may be felt, but this is a normal process - no medications are required. If there is increased nervous excitability, the pain threshold is low - you can take sedatives and painkillers (be sure to discuss this issue with your dentist!).

Diagnostics before installing crowns is necessary

Diagnostics

Clinical assessment of the oral cavity and tooth damage is a mandatory step before installation. This is an examination, the manipulations are painless. Orthodontist:

- examines the tooth, checking the severity of the midline (equator), the degree of destruction;

- notes fillings, degree of tooth mobility;

- identifies defects in bite and dentition;

- checks the distribution of occlusal load;

- pays attention to periodontal disease.

An x-ray may also be needed if there is inflammation or a suspected tumor. If there is no inflammatory process (it must be eliminated before installation), the tooth is cleaned of plaque and caries is treated. They are filled, if necessary, removing the nerve and additionally filling the canals.

Tooth preparation

Preparing a tooth for a metal-ceramic crown means grinding off part of the tooth so that the crown placed on top is in line with the rest of the teeth and does not interfere. The walls are shortened and smoothed, the tooth shape becomes cylindrical.

If the tooth root is healthy, the nerve is not removed. They try to keep the tooth alive, then it will not “dry out” under the crown - the service life of the metal-ceramics will increase. The abutment tooth for a metal-ceramic crown is prepared much more than when preparing to install an all-ceramic crown. Focus on the rules:

- The color of the structure, close to the natural tooth, is obtained by distributing the thickness of the ceramic: center - 1.3-1.4 mm;

- cutting part - 1.5-1.6 mm.

Like any dental procedures in the mouth, preparation is not the most pleasant, but it does not cause severe pain. At the patient’s request, the doctor will always inject an anesthetic to make him feel comfortable. When the preparation is not gentle, a significant amount of enamel and dentin (about 2 mm of hard tissue) is ground off; full anesthesia is performed with a living (intact) pulp.

Taking an impression, installing a temporary prosthesis

The orthodontist needs an impression of the upper and lower jaws to correctly make the crown so that the prosthesis is not perceived as something foreign. On the model made in plaster according to the cast, the height of the product, the angle of inclination, and the evenness of the dentition will then be checked. Sometimes an impression is made of the antagonist teeth and only the jaw where the crown will be installed.

Impression of teeth for making crowns

When making such crowns, impressions are used consisting of 2 layers:

- indicative (basic);

- clarifying (correcting).

First, gum retraction is performed under anesthesia to move it away from the tooth. The most painless method is mechanical, when the gum tray is opened using a thread soaked in a retraction compound. The groove opens, exposing the space between the tooth and the soft tissue.

An inlay is placed on the tooth, since any crown can be installed on it. The first impression is made using impression material and a special tray with perforations. Then the retraction thread is removed, a second layer (corrective) is applied, and the impression tray is again placed on the dentition according to the dental impressions. While the crown is being made, the orthodontist will install a temporary composite, and the patient will wear it for 1-2 weeks.

Manufacturing of a metal-ceramic crown

Stages of manufacturing a metal-ceramic crown:

- Creating a Casting Mold

- Formation of a metal frame

- Application and fixation of dentin, enamel, transparent layers

- Retouching with dye does not imitate carious lesions, only the necessary natural darkening.

The frame is modeled using different methods. For example, the Adapt method. The metal base is obtained by pressing a stamp. A more “jewelry” method is wax modeling. To make a metal-ceramic crown, a mock-up is first prepared from wax that accurately depicts the contours of the finished crown. Then the wax is cut off (this creates a platform for the ceramics), and a fireproof mold is prepared for casting.

The frame of the metal-ceramic crown, which has cooled after casting, is carefully removed and cleaned of the remains of the molding material, dissolving them in an acid solution. The sprue channels (through which the melt was poured into the mold) are removed and sent for a 10-minute firing. The temperature in the oven is 950-1000°C. After cooling, the metal base is adjusted to the required dimensions on the supporting tooth and ground.

Features of manufacturing a metal frame depend on the type of material:

- Soft alloys with a gold content of more than 70%. To prevent the appearance of bubbles on the surface, the finished area for ceramics is treated with a cutter or carbide boron, cleaned with steam, a solvent (for example, carbon tetrachloride or chloroform).

- Alloys of gold-palladium, gold-palladium-silver, palladium-silver and palladium-copper. Their peculiarity: they can change the color of the finished crown. Silver can “color” ceramics yellowish; copper will give a greenish tint. The finished area for the ceramic mass is treated with corundum grinding heads, cleaned in a sandblaster, and small deposits and dust are removed with steam or an organic solvent. Palladium in the base of most alloys absorbs (absorbs) air; when fired, oxygen, nitrogen and hydrogen are released, forming bubbles on the surface. Therefore, the formation of the frame includes the stage of vacuum heat treatment (degassing), when the temperature is maintained at 1000°C. The surface darkens to black.

- Nickel-chromium alloys. Corundum heads are used in processing. The ground frame is then heated to form an oxide film on the surface. Next, the metal base is polished with aluminum oxide particles using a microsandblaster and cleaned with a solvent or steam cleaner.

An opaque mass is applied in thin layers to the prepared metal-ceramic crown frame, which forms the dentin layer. For a natural depth of color, as in a healthy tooth, the first layer is the contour of the crown, setting the shape by cutting off the excess.

Further production of the metal-ceramic crown and ceramic superstructure is divided into 2 volumetric stages:

- Application of dentin coating followed by modeling.

- Condensation, i.e. vibration (for uniform distribution), blotting off excess moisture with special napkins and drying under a stream of hot air.

Manufacturing of metal-ceramic crowns

“Finger-shaped” grooves, which are very clearly visible under the enamel of a real tooth in young people, are obtained by cutting off small sections from the workpiece and smoothing the cuts with a brush. To give the metal-ceramic crown the effect of opalescence (dispersion of light), a lighter enamel mass is applied in the next layer. The final layer is colorless; it is this layer that gives the crown transparency and depth comparable to natural tooth enamel. The technician can even draw cracks (relevant for older patients), darken some areas (intertubercular space and cervical area) so that the metal-ceramic crown in the dentition looks natural.

Fitting and fixation of a metal-ceramic crown

Before installing a metal-ceramic crown, the patient wears a temporary one. All this, together with the temporary cement, is cleaned and the stump is dried. To prevent saliva from getting onto the base, a retraction thread is used. First, simply put on the crown to check the tightness of the fit. Only then does the final fixation of the metal-ceramic crown take place.

Each orthodontist has its own quality control. Some use a strip of paper, others check the installation with dental floss (a piece of paper, thread is held tightly between the teeth). After installing the crown, it is advisable to refrain from eating for 2-3 hours.

Types

The following types of structures are distinguished:

- Coated with gold prostheses.

Sprayed bridge

- Without spraying - they look like polished metal.

Solid cast bridge without spraying

- With lining - has a composite or plastic lining on the front surface. There is a drawback - the risk of cracks and chips.

Solid cast bridge with veneer

- Combined - the design can be solid in the area of the chewing crowns and ceramic in the smile area to improve aesthetics.

Combined dentures

General overview

Bridges, or “bridges,” belong to the category of fixed prostheses designed to replace missing elements of the dentition. The design of the soldered prosthesis consists of a cast intermediate part, which serves as the basis for fixing metal crowns made by stamping. Soldered together, the elements form a durable system fixed to the supporting units.

For the manufacture of stamped crowns, template blanks made of anti-corrosion steel or gold are used. In situations where the dentist’s task is to eliminate excessive mobility of adjacent teeth, a soldered prosthesis is used. If the jaw row is characterized by the presence of edentulous areas, a metal intermediate part is used to replace them.

Preparation for prosthetics

Preparation for the installation of an orthopedic structure can be therapeutic, surgical, orthopedic and orthodontic. Types of preliminary sanitation can be combined, depending on the condition of the oral cavity and the type of defect.

How do you prepare for prosthetics at the dentist:

- Assessment of oral health.

- Carrying out professional cleaning to remove hard dental deposits.

- Carrying out anti-inflammatory therapy if necessary.

- Removal of carious cavities, treatment of pulpitis, periodontitis and other existing pathologies of teeth and mucous membranes.

- Depulpation of teeth (according to indications).

The surgical type of preparation includes the following activities:

- Removal of teeth that cannot be treated. Indications include chronic periodontitis, cysts, and pathological mobility of crowns.

- Removal of soft tissues due to their hypertrophy (hypertrophic gingivitis).

- Complex treatment of dentofacial pathologies.

Orthodontic preparation includes returning the normal bite of healthy teeth through the use of braces, aligners, and plates. Treatment is necessary to correct the position of individual abutment crowns and to create space in the oral cavity for fixation of the bridge structure.

The orthopedic preparation stage includes procedures such as:

- Making corrective aligners to move the advanced crown to the opposite side where the tooth is missing. In this way, the orthopedist creates a place to install the structure.

- Making functional mouthguards to relax the masticatory muscles. Such an event is indicated for hypertonicity in order to prevent breakage of the bridge after installation.

How much does a dental bridge cost?

Moscow prices for bridges consist of the cost of the casts required for the manufacture of the structure, the prosthesis itself, its fitting and installation. The cost of the dental bridge itself depends, first of all, on the material used. Thus, the most budget option is plastic, but plastic structures are used only as temporary prostheses, the most expensive are all-ceramic bridges with a zirconium dioxide frame, metal-ceramics are inferior to them in cost, but practically not inferior in quality. Also, how much a dental bridge costs is influenced by the price category of the dental clinic where a dental bridge can be made in Moscow. Thus, installing the most budget bridge in economy class dentistry will cost an average of 3,000 rubles, and in a VIP clinic prices will start from 20,000 rubles for a structure consisting of two supporting crowns and one artificial tooth between them. You can find out how much it costs to install a dental bridge by reading the price list on or by calling our clinic directly. The administrator will also tell you what is included in the price and which procedures are paid separately.

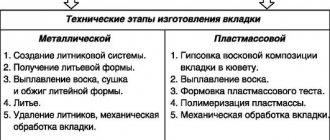

Clinical and laboratory stages of manufacturing a bridge prosthesis

Stages and their features (K - clinical, L - laboratory):

- K - the dentist makes a diagnosis, selects the type of construction together with the patient, prepares the abutment crowns, after which impressions are taken.

- L - creation of a plaster model, selection of the color of the prosthesis, creation of a temporary structure.

- K - fitting the temporary product, checking occlusion.

- L - casting of a permanent bridge structure.

- K - fitting of the prosthesis.

- L - cladding or spraying.

- K - installation of the structure in the oral cavity, assessing the quality of its fit, fixation with special cement.

The prosthetic procedure will require 2 visits to the dentist’s office:

- First. The defect is assessed, the doctor considers the optimal restoration options, and clarifies with the patient which restoration method is preferable. On the first visit, the oral cavity is sanitized and the supporting elements are ground. The dentist takes impressions, sends them to the laboratory and places temporary aligners.

- Second. The dentist places a ready-made solid bridge, finds out how well it fits the patient, and whether there are any defects. When everything is in order, the structure is fixed with composite cement.

Important! When there are inflammatory pathologies of the mucous membrane or other relative contraindications, several visits to a specialist will be required until the problem is eliminated.

If the quality of the finished product does not match, it will require correction. In this case, prosthetics will also be extended over more than two visits.

Manufacturing technology

The method of creating soldered dentures involves going through several stages, which necessitates repeated visits to the dentist.

Formation of impressions

Before proceeding with prosthetics, it is necessary to process the elements of the dentition selected as support for the future bridge. Removing the enamel layer allows the units to be cone-shaped. At the same time, the doctor checks the parallelism of the supports, without which it is impossible to achieve tight fixation of the prosthesis. After preparation, plaster impressions are taken from the jaw region, which are used to design a replacement structure.

Model making

Based on the obtained casts, a plaster model is formed, reflecting the features of the anatomical structure of the patient’s dentition. The doctor determines the central occlusal line using wax templates, after which the model is fixed in the occluder. The hardened gypsum undergoes additional processing, after which the stumps of the prepared elements are formed on the base, on which the fastening crowns will be placed.

Casting and soldering of the prosthesis

The soldered bridge is made in a foundry, where the wax elements are replaced with metal structures. After melting the wax and drying the model, it is filled with a steel alloy, while the finished elements are freed from the previously applied refractory mass and parts of the gating structure.

To connect finished parts, solder is used, which has a lower melting point. An important condition is compliance with the technical characteristics of the composition, which must be resistant to alkaline environments and corrosion, be combined with metal shades, and also ensure the possibility of mechanical operation of the structure under loads.

Finishing

Upon completion of soldering, the finished prosthesis is washed from residual elements of the refractory mass and bleached in a hydrochloric acid solution, after which it is subjected to mechanical grinding. The final stage of polishing involves the use of a special Goya paste, which gives smoothness to the external structure of the structure.

Soldered bridges are affordable and do not require the use of complex equipment during the manufacturing process, but they have low aesthetics, and in some cases they create an off-flavor due to the use of different types of metal. The cost of creating one crown varies in the range of 1.2-2 thousand rubles.

Installation process

The entire installation process of a solid cast structure includes the following activities:

- Sanitation of the oral cavity.

- Turning of abutment crowns using anesthesia. About 1.5 mm of tissue is removed. The crown is given a special shape for a secure fit of the prosthesis.

- Taking an impression.

- Trying on a temporary prosthesis with its subsequent fixation.

- Trying on a permanent structure and checking the quality of fit.

- Fixation of the permanent structure with cement.

Advantages and disadvantages

| pros | Minuses |

| Homogeneous design, lack of solder, which increases the strength of the product. Unlike other prostheses, solid ones almost never break, because there are no weak joints | Low aesthetics |

| High strength and durability | The cost is higher than a cast prosthesis |

| Tight fit to the tooth, which prevents food particles from getting under the crown, and this prevents secondary caries and destruction of enamel under the prosthesis, and also reduces the likelihood of damage to the structure | Great thermal conductivity |

| High functional efficiency due to precise modeling of support elements and intermediate parts | Risk of discomfort when eating hot food |

| No darkening factor in the structure in the soldering area | Cannot be determined in case of metal allergy |

| Wax can be used to thicken the walls of an orthopedic product. | The need to grind healthy crowns, which over time leads to their destruction due to malnutrition |

| The one-piece design is better tolerated by patients, the risk of prosthetic stomatitis is reduced | High load on abutment teeth can cause them to become loose |

A dental bridge fell out: what to do?

Dental bridges, as well as dental crowns, as well as other orthopedic structures, have a service life, after which they must be replaced. Modern materials and manufacturing and installation technologies make the shelf life of orthopedic structures quite long, but this does not negate the mandatory removal of a dental bridge whose shelf life has expired. Unfortunately, many patients, if not the majority, ignore the need to remove the bridge and replace it with a new one until the problem becomes a rib, that is, until the dental bridge falls off.

A timely, regular visit to the dentist will help to avoid such a problem, who will be able to detect that the dental bridge has become loose or has begun to collapse, before the patient feels it himself. The fact is that the shelf life of a bridge is limited not so much by the properties of the manufacturing material itself (with proper care it is practically not subject to erosion), but by the fragility of the composite materials with which the lateral crowns of the bridge are attached to the supporting teeth, as well as the danger of development under these crowns secondary caries, which is aggravated by the fact that the supporting teeth are most often “dead”, pulpless, which reduces their resistance to carious lesions. So how is a dental bridge removed? Considering that after removing the bridge, a new one needs to be installed in its place (in rare cases, it is possible to install the same structure if it is not damaged, but with fresh cement), it is very important not to damage the supporting teeth in order to avoid even further grinding of them. For this purpose, special ultrasonic devices are used, which cause the cement between the crown and the tooth to crumble, after which the bridge is removed.

If the dental bridge breaks and falls off, you must immediately consult a doctor, since the ground supporting teeth should not be open, this will lead to their damage, in addition, the bridge could become detached traumatically, and only a specialist can notice and correct this.

Very often on various forums you can come across the question: “What to do if the dental bridge is wobbly?” The answer is simple: consult a doctor immediately. Perhaps the installation technology was violated or the design was not accurately adjusted to the ground abutment teeth. If the dental bridge begins to sway several years after installation, this may indicate the presence of the above-mentioned secondary caries or partial destruction of the cement between the crown and the tooth tissues.

It is also necessary to consult a specialist if you experience toothache under the bridge. This is another sign of secondary caries. If the gums hurt at the point of contact with the central part of the bridge, perhaps the structure was set too deeply, which caused rubbing of the soft tissues by the edge of the bridge, and this in turn can lead to the formation of bruises and bedsores, and in advanced cases, to an inflammatory process.

If chips or microcracks have formed on the artificial enamel of a dental bridge (in the case of ceramic and metal-ceramic structures), it is most often possible to repair dental bridges with composite materials directly in the patient’s oral cavity. In some cases, it is also possible to repair structures made of plastic and metal-plastic. WARNING: If you swallow a dental bridge or a fragment of it, go to a clinic or emergency room. An ultrasound examination of the gastrointestinal tract may be required, since the sharp edges of the chips can damage the mucous membranes of the stomach, esophagus and intestines.

Contraindications

One-piece denture in the mouth

There are relative and absolute restrictions that do not allow the installation of a solid-cast bridge. The first include conditions that this method of recovery completely excludes. Relative contraindications are considered individually.

A solid-cast bridge is not used in the following conditions:

- defects when more than 1 molar, 2 premolars and 4 incisors are missing;

- infectious and inflammatory pathologies of the jaw bones, including osteomyelitis and osteoporosis;

- psychological illnesses that do not allow the patient to take care of himself, as well as epilepsy;

- oncological diseases;

- pathologies accompanied by blood clotting disorders;

- allergy to the materials used or anesthetic substance.

Relative restrictions to this recovery option will be:

- teeth grinding at night or bruxism;

- acute period of inflammatory pathologies of the oral mucosa;

- poor oral hygiene;

- pathological abrasion of enamel;

- severe pathologies of periodontal tissues with frequent relapses;

- abnormal dental bite that cannot be corrected.

Service life and care

With proper care, a solid-cast bridge can last for 15 years without breaking. The service life of such a product is practically unlimited, but it is important to visit a doctor regularly in order to identify problems in time and solve them at the initial stage.

What you need to do to properly care for a solid bridge:

- regularly clean your mouth in compliance with standard hygiene rules;

- use a toothbrush, dental floss and a special brush daily to clean the spaces between the gum and the structure;

- use an oral irrigator several times a week;

- visit the dentist every few months for professional oral hygiene and assessment of the condition of the orthopedic structure;

- rinse and clean the mouth after each meal, for which it is enough to use a deodorizing mouthwash or a solution prepared at home from herbs, which will prevent inflammatory diseases.

Important! Installation of a one-piece denture makes it impossible to carry out standard professional oral hygiene. The dentist uses special cleaning products and brushes to clean your teeth. It is also unacceptable to use the irrigator in high pressure mode, directing the stream at the prosthesis.

Solid bridge

The product is made using special casting. The advantage is that the crown itself fits firmly to the ground tooth, so the places in contact with the gum and possible gaps are not clogged with food debris.

This type completely eliminates destruction. There are also disadvantages to this design. This is primarily a great sensitivity to hot. A person experiences discomfort when eating hot food.

Price

The approximate cost of a solid-cast bridge varies from 7,000 rubles. The price differs depending on the length of the defect and the metal alloys used.

The cost will be higher if the structure is additionally coated with ceramics to improve the appearance. Also, the price differs for combined dentures and products with veneering.

To choose a prosthetic method, consult an orthopedic dentist. The doctor will conduct the necessary research, select which prosthesis is best suited in a particular situation, and tell you about all the intricacies of subsequent prosthetics.

How much do metal-ceramic crowns cost?

The cost of metal ceramics consists of:

- metal base (a gold frame, of course, costs more than a palladium alloy);

- ceramics (the price of ceramic mass depends on the manufacturer. For example, a jar of MC Emotions Opaque powder - 3200 rubles for 20 g);

- volume of work of a dental technician;

- electricity costs (firing);

- depreciation;

- additional expenses (taxes, rent, payment for third-party services).

As a result, the approximate cost of manufacturing a fixed metal-ceramic prosthesis is from 5,000 rubles. And then you need to add the price for diagnostics, preliminary treatment, preparation, installation. The total cost of visiting a dental clinic (1 crown) can reach 250 thousand rubles.

Prices on the website of any clinic are approximate. Each case is individual, so it is better to prepare in advance for an increase in costs by about a third.