Chief editor of the site:

Snitkovsky Arkady Alexandrovich

Chief physician of the professorial dentistry “22 Century”, dentist, orthopedic dentist

Author of the article:

Scientific team of dentistry “22 Century”

Dentists, candidates and doctors of medical sciences, professors

Plate prosthesis

A plate prosthesis is the most common of the simple and affordable methods of removable prosthetics for complete or partial absence of teeth. Let's look at the materials and stages of its manufacture.

What is a plate prosthesis made of?

To begin with, let us recall the general requirements for the material:

- No impact on the oral mucosa and the body as a whole;

- Aesthetics;

- High strength, low abrasion;

- Preservation of shape during use;

- Easy to care for;

- No unpleasant taste or smell;

- Must be repairable;

- Must be technologically advanced.

Plate dentures consist of a base (foundation) and artificial teeth. Also, in case of partial absence of teeth, support-retaining elements (clasps) .

The base is made from:

Acrylic plastics

Plastics are polymers that represent a large group of high-molecular compounds obtained chemically from natural materials or by chemical synthesis from low-molecular compounds. One of the properties of polymers is their high manufacturability, the ability to be molded under heat and pressure and stably retain their given shape, which explains their widespread use in orthopedic dentistry. Plastics are made from powder and liquid.

Advantages:

- Affordable price;

- Simple manufacturing technology (various color and size combinations are possible);

- Short production time for the prosthesis;

- Easy to care for.

Flaws:

- With prolonged use of the structure, the material begins to release special substances that can cause a local allergic reaction;

- Acrylic plastics are porous compounds. With poor oral hygiene and poor-quality care of the prosthesis, it becomes contaminated with microorganisms, which helps to reduce local immunity. And this can cause the development of inflammatory diseases of the oral mucosa;

- Possibility of injury to the soft tissues of the oral cavity.

Nylon

Nylon removable dentures

Nylon is an elastic material.

Advantages:

- Hypoallergenic;

- High aesthetics (complete imitation of natural teeth and gums);

- In case of partial absence of teeth, the supporting teeth are not treated;

- The flexibility of the material ensures a short adaptation period and also has the least mechanical impact on the soft tissues of the oral cavity;

- Easy care;

- When used carefully they last quite a long time.

Despite the significant positive qualities, nylon prostheses have their disadvantages :

- The fixing elements do not transfer the load to the remaining teeth. As a result, the mucous membrane takes on the chewing load, which leads to gradual periodontal damage and further inflammatory process;

- The absence of a rigid frame leads to the fact that chewing pressure is distributed unevenly. Subsequently, this leads to atrophy of the bone tissue of the jaws;

- For technological reasons, nylon prostheses are not polished. This design absorbs and retains foreign odors;

- Frequent adjustments are necessary;

- High price.

The material for the base is selected based on the individual characteristics of the body and the condition of the oral cavity.

Indications for use

Indications for the use of prostheses with a metal base can be twofold: general medical (biological) and special. General medical indications include: allergies, bruxism, occupational characteristics, intolerance to plastic prostheses. Special ones include:

frequent breakdowns of plastic bases, multiple, small included defects in the dentition;

- replacement of central or lateral incisors;

- narrowing of the jaws;

- negative attitude towards continuous clasp;

- lack of even one distal support on the upper jaw;

- high attachment of the frenulum of the tongue;

- low clinical dental crowns.

Doctors suggest using removable dentures with a metal base in the treatment of patients with deep bites and maxillofacial patients (after resection of areas of the alveolar processes or jaws).

Features of patient examination. From the anamnesis, it is necessary to find out whether the patient has an allergic background, intolerance to acrylic plastics, whether the patient is undergoing prosthetics for the first time or repeatedly. The patient's feedback on old dentures and their general attitude towards removable plastic dentures are also taken into account.

Artificial teeth

Laminar dentures

For laminar dentures, artificial teeth are made of plastic.

There are frontal (front) and chewing (root) groups, produced in sets in headsets.

Plastic teeth are very similar in appearance to the enamel of natural teeth. During production, you can vary the color and shade. Artificial teeth are firmly connected to the base due to the homogeneity of the material (their connection occurs during polymerization of the base plastic). They are also easy to adjust both by a technician in the laboratory and by a doctor when handing over the prosthesis. Headsets are available in several styles and shades, many combinations are possible. Due to this, it is possible to harmoniously select and manufacture a prosthesis according to the individual parameters of the face.

Over time, the technology for making artificial teeth has progressed.

proposed to produce acrylic artificial teeth using the injection-compression method (continuous injection of material during polymerization to compensate for its shrinkage, followed by compaction of the material to a homogeneous state). This makes them incredibly durable.

The Ukrainian company produces artificial teeth in the form of a set in Estedent, Estedent-02. They have the following positive properties: imitation of the anatomical shape and color of the tooth; high strength indicators; fluorescent effect (both in natural and artificial lighting). Estedent-D is used for prosthetics for children during the period of temporary and mixed dentition.

“Executive” artificial teeth (“Dentsply”, USA) have five distinct shade zones, which will allow you to imitate natural teeth as accurately as possible.

Also in our country, headsets “Megastar” (Great Britain), “Ivoclar” (Liechtenstein), etc. have found use.

When selecting artificial teeth, not only the color of natural teeth (if any) is taken into account, but also the shape of the patient’s face and constitution. Thanks to a wide selection of artificial teeth in color and shape, an individual approach to each clinical case is possible.

Device structure

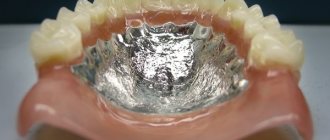

The base is made of acrylic plastic used for medical purposes. Often a metal alloy is included in the base or reinforcement is made, this allows improving the technical properties of the material:

- the strength of the apparatus increases;

- characterized by high thermal conductivity;

- has increased hypoallergenicity.

The element must have a certain structure that will guarantee long-term operation of the device and make its use more comfortable for the patient:

- for correct, uniform distribution of pressure when chewing;

- the material should minimally adsorb elements of saliva and food residues;

- a base that is convenient for easy and quick cleaning of the material with specialized means;

- strength characteristics must be high;

- the elasticity must also be sufficient, since the material is modeled under the alveolar process of the jaw arch;

- the plasticity of the apparatus should be minimal;

- an increased level of biocompatibility of the material is necessary to eliminate unwanted reactions of the body.

Clasps

Clasp denture with clasps

In case of partial absence of teeth, one of the ways to fix the prosthesis in the oral cavity is the presence of clasps. They are usually made of metal. They tightly cover the tooth, can only serve as a retaining element, and also act as a support, that is, transmit chewing pressure to the tooth. Noticeable when talking and smiling.

Clasps made of elastic material (nylon dentures) can only perform a retaining function. Excellent aesthetics, but unreliable and can become deformed and break.

Advantages

The metal base is more durable, and the structure can serve its owner for many years without losing its performance properties. This prosthesis has other advantages:

- Reasonable price;

- Prevention of gum diseases;

- The ability to combine prosthetics with dental treatment;

- Easy maintenance of the structure;

- Possibility to leave the denture in the mouth overnight.

The prosthesis is fixed in the mouth using clasps or attachments. Clasps are hooks attached to the very base of the supporting teeth.

Stages of manufacturing a plate prosthesis

- Conversation with the patient (it is necessary to clarify complaints, the presence of chronic diseases, allergic reactions, etc.);

- Examination of the oral cavity, assessment of the condition of soft tissues and level of hygiene;

- Additional studies (radiography, tests, etc., if necessary);

- Selection of design;

- Taking impressions from the upper and lower jaws;

- Making a plaster model, then a wax template with bite ridges;

- Trying on in the oral cavity, determining the relative position of the jaws, the color and shape of the teeth, choosing fixing elements (if there are preserved teeth);

- Strengthening models into an articulator, placing artificial teeth on a wax base, placing fixing elements in the base;

- Try-on in the oral cavity, correction if necessary;

- Replacement of wax with the final material, processing, polishing of the prosthesis;

- Fitting in the oral cavity, correction. Recommendations for care.

Plate dentures have proven themselves to be affordable, quick to manufacture and aesthetic designs.

Date of publication: September 20, 2020 Last update: September 22, 2022 © 2020 Professorial Dentistry “22 Century”. All rights reserved.

Features of the denture base

The denture base is attached to the human anatomical structures:

- on the upper jaw with the alveolar process and palate;

- on the lower jaw only with the alveolar process.

In addition to the function of attaching to the patient’s jaws, the elements perform a number of additional functions:

- basis for attaching the structural elements of a denture (guide plates, artificial teeth, frame, fastening);

- transfer of sensitivity during chewing to living human tissue;

- replacement of damaged gingival tissue, which forms a static function;

- support for tissues in case of operations on the face and mucous membranes.

The base is a frame for a denture, without which it is impossible to install them.

Reinforced denture - what is it?

The task of reinforcing (or strengthening) a denture is not only to give the denture extra strength, but also to make it possible to hold all the key components of the product together when the denture breaks.

Clinical cases.

Removable dentures in Moscow are most often made of plastic. This is partly why the prosthesis is not so durable in relation to mechanical damage. Therefore, with strong impact, cracks and even fracture of the base (or base) are possible. Reinforcement of a denture consists of placing a plastic base inside a metal mesh, which gives it additional strength.

Prostheses with a reinforced base - their types.

The reinforcement option for a complete removable denture is determined by the type of alloys used.

- As a rule, a metal mesh is used to reinforce plastic prostheses.

- The strength of acrylic bases is increased through the use of metal spacers, aramid threads, and fiberglass.

- The most commonly used reinforcing element is considered to be a mesh made of noble metals, which prevent allergies and have excellent compatibility with other materials.

When is it necessary to reinforce a prosthesis with mesh?

The presence of reinforcing elements in a denture does not cause inconvenience to the patient, since they are contained inside the denture itself. In terms of ease of use, reinforced removable dentures are exactly the same as ordinary dentures. Well, the strength properties are significantly superior. Despite the fact that the prosthesis remains removable, its functional part is of great importance. That is why, when making prosthetics, it is advisable not to neglect the possibility of reinforcing the prosthesis. Dentists recommend making a reinforced removable denture:

- when the product is intensively exposed to various mechanical parameters (reinforcement increases resistance to cracks and strength under static loads);

- with complex anatomical and typographical characteristics of the patient;

- to hold weak teeth (periodontal disease, trauma);

- with severe shrinkage of the prosthetic material (which may cause poor fit of the prosthesis to the gum and the occurrence of inflammatory processes in the tissues).

Stages of manufacturing a prosthesis with a reinforced base

The standard start to any dental procedure is an oral health assessment. The significance of denture reinforcement is analyzed based on the calculation of the likely loads on the supporting teeth. Laboratory stages of reinforcement are calculated depending on the target orientation - obtaining a strong and high-quality prosthesis, maintaining the functionality of the dentofacial system. The key preparatory point is the choice of a reinforcing mesh option that meets the following characteristics:

- duration of use;

- anatomical compatibility;

- possibility of detailed processing.

Reinforcement process In the laboratory part, the reinforcement stages represent the introduction of reinforcing elements into the base material, giving the product reliability and strength. In case of multiple defects in the dentition, the saddle-shaped part of the prosthesis is strengthened, since reinforcement of only the beam part does not lead to additional strength. This reinforced removable denture takes about a week to complete. The product is fixed to the supporting teeth, which is why the elements reinforcing the prosthesis must have greater strength and minimal load. You can care for a reinforced removable denture in the same way as a standard removable denture.

You can see the cost of denture reinforcement in Moscow on our website in the Prices section. Consult on the installation of a reinforced prosthesis at our Clearstom dental clinic by calling or. Call and make an appointment!