Slime, hand chewing gum, slime, handgam or “anti-stress” toy, as you name it, is a sticky substance that appeals to children due to its soft texture and attractive appearance. A budget option is to make a jelly-like substance at home, implementing the idea and putting in the effort. A very young child can resort to the help of an adult. The older ones can cope on their own, giving mom an hour of rest.

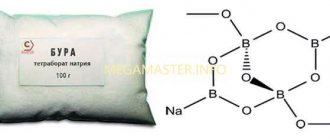

Sodium tetraborate base

The inorganic boron compound (Na2B4O7) is widely used in medicine, the chemical industry, cosmetology and food production, and now in the manufacture of toys. Auxiliary components change, and the technological process cannot be completed without sodium tetraborate, which is freely sold in pharmacies and acts as a thickener.

Borax has become in demand, and products based on it are modified and supplemented with simple recipes that are accessible even to children. Their selection will help make slime from sodium tetraborate and show the creative inclinations of young “chemists”, and will significantly save the family budget.

Flaws

- After use, a deposit of salts forms, which must be removed mechanically;

- It is necessary to choose storage areas that are free of moisture, since high humidity will cause the flux to deteriorate;

- To prepare the material for use, you need to spend time and choose the right proportion, which can lead to errors.

Varieties of Borax

There are two main varieties that relate to the appearance of the material. The first option is the solid form. Borax soldering flux is supplied in the form of a powder with fine solid fractions. Thanks to this, it is easy to lay it on the metal surface before soldering in the required quantity and it will not spread at the same time. This variety is supplied in a special box that protects the material hermetically from the penetration of moisture and other foreign factors. Fractions are white.

Soldering borax in powder form

The second type, which is more often used for lighter metals and their alloys, is diluted borax. In this case, you are offered the same material, but dissolved in liquid. Due to this, it can be used at lower soldering temperatures. Using this type is also easier, since small parts are simply dipped into the liquid, after which they can be soldered. This is used both in the jewelry industry and in other places where small items are worked. Contacts, wires and other types of equipment come into good contact with dissolved flux. Despite the fact that the principle of using borax for soldering in liquid form is somewhat different from the standard one, they have almost the same effect.

There are also varieties in the form of mixtures, when other fluxes are also used. This is necessary in cases where it is impossible to achieve the desired results using one substance. Proportions and composition depend on specific goals. Most often it is combined with boric acid.

Composition and physicochemical properties

The composition of borax for soldering includes sodium chloride and barium chloride, in some cases boric acid is added to it. It is not used in its pure form for all procedures, since this would require too high a melting point. Drill soldering powder is a high-temperature flux, so its main property is resistance to high temperatures. It is worth noting that the material perfectly retains its chemical properties even at a lower concentration than what is supplied. Thus, the flux solution has a fairly high level of dissolution of the oxides of all base metals for which it is used.

It can also dissolve fatty films and other unnecessary things that will interfere with the normal soldering of the material. Brown soldering protects against many types of defects that can occur in work.

Specifications

There are two main grades of the substance, which are defined according to GOST as grade A and grade B:

Soldering of metals is carried out by first removing traces of oxides from their surface. Fluxes are used for this. They should prevent oxidation when heated and encourage good flow of molten solder.

For soldering copper products, borax solder ideally meets all requirements. The substance has been known since the Middle Ages. It was mined in the lakes of India and Tibet, then transported to Europe, where it was used for processing fabrics and leather, and producing glass.

Borax is widely used for working with metals. When manufacturing or repairing metal products, borax soldering is carried out. First of all, the method is used for parts made of copper and brass. A special type of this flux is used when repairing jewelry.

Original slime

The classic version includes only two components. It will take no more than a minute to implement the idea.

Compound:

- PVA glue (100 ml);

- sodium tetraborate (a few drops).

Recipe:

- In a convenient plate, combine the base with the thickener and mix vigorously. Add tetraborate drop by drop to achieve the desired consistency.

- Take the raw material in your hands when it starts to detach from the walls and knead it.

Sodium tetraborate can be replaced with lens fluid. You need to buy a high-quality adhesive base, and it is best to store the substance in the refrigerator. The classic version of “Velcro” assumes naturalness, but if you want to be spectacular and original, use paint or nail polish of any color.

Stone care

When using borax, you must take precautions: store in a closed container in a dry, dark place, use protective gloves when working and avoid contact with skin and mucous membranes.

Previous article Mineral brookite - properties, deposits and applications Next article Mineral vanadinite - properties, significance of the stone and applications.

Sources

- https://pressadv.ru/samodelkinu/bura-formula.html

- https://stroy-podskazka.ru/pajka/bura/

- https://ArmRinok.ru/obrabotka/bura-v.html

- https://m-strana.ru/articles/bura-formula/

- https://WikiMetall.ru/spravochnik/chto-takoe-bura.html

- https://kamneteka.com/bura-svoystva-znachenie-i-primenenie/

- https://pressadv.ru/stali/bura-tehnicheskaya.html

With glycerin

Even beginners can make their own crispy and flexible toy from sodium tetraborate and glycerin.

Ingredients:

- water (1 tbsp);

- shampoo (1 tsp);

- the same dose of glycerin (1 tsp);

- PVA glue (5 tsp);

- sodium tetraborate (can be replaced with naphthyzine and soda);

- glitter (optional).

Recipe:

- Pour the liquid ingredients into a bowl, stir and beat.

- Introduce glue into the foaming mass using a spoon.

- Add thickener portionwise, bringing to consistency.

- Add elasticity by kneading with your hands.

Glycerin will make the handgam pliable and unusually soft, and the addition of glitter will add unusualness and beauty. In addition, glycerin is able to “breathe” life into a hardened product.

Starry sky

To make this slime, you need to stock up on blue dye, as well as silver sparkles of different sizes. In addition, you will need PVA glue and Borax.

This hand chewing gum is made according to the classic recipe. Before thickening, the glue must be mixed with dye and glitter. After adding the activator, you get a beautiful toy with a pearlescent sheen.

Eco-friendly matte slime

A small child will like the toy, as it develops motor skills, and is also non-toxic, so it will not cause allergies.

Components:

- PVA glue - 60 g (4 tbsp);

- corn or potato starch – 25 g (full 2 tsp);

- shaving foam (2 tbsp.);

- sodium tetraborate (up to 5 drops);

- dye.

How to do:

- Combine glue and dye in a deep bowl.

- Add starch and stir until the cream becomes thick.

- Squeeze out shaving foam and sodium tetraborate, thickening the mass.

To add elasticity, you can add a few drops of essential or vegetable oil.

What is this substance needed for?

Sodium tetraborate is the sodium salt of boric acid, which is highly soluble in water. Tetraborate appears as a white crystalline powder and is used to treat fungal infections. Boric acid salts are often used to make slime. The substance plays the role of an activator, which accelerates the thickening of polymers and polysaccharides. As a result, the toy becomes viscous, viscous and elastic.

Borax tends to accumulate in the skin, so you need to wear gloves when making slime. Otherwise, it will lead to an allergic reaction.

Handgam “glass” or in color (tested recipe)

Stationery glue, when used correctly, is non-toxic and safe for children. This base will give the toy a rich white tint, and when pulled out during play, it will become transparent. Keeping the slime in a hermetically sealed container for 3 days will give it the glass effect.

Components:

- transparent glue (30-50 ml);

- water (2 tsp);

- liquid soap (4 short sprays) or 1 tsp. shampoo;

- sodium tetraborate;

- dye (watercolor paints) optional;

- glitter (optional).

Tried recipe:

- Squeeze out the glue and pour water into the container.

- Add soap (shampoo) and shake. At this stage, you can optionally add dye if you need bright slime.

- Pour in the thickener and stir.

- Knead well with your hands.

Adding glitter will give the slime a festive and glowing effect.

History of creation

Handgam was first introduced in America back in 1976. The company that created this toy invested a huge amount of money in promoting the product, but in those years such an invention did not gain popularity. But nowadays everyone knows about such a wonderful toy, more and more people are trying to make it themselves, because in the process of creation you can not only get a sea of new impressions, positive emotions and emotions, but also new knowledge in the field of chemistry. And when using slime, you can gain knowledge in the field of physics and find out what feature is found in a non-Newtonian liquid.

Embossed fluffy with starch

The best choice for a child is a transforming slime fun that develops imagination. Adding lotion to slime with sodium tetraborate will give it shine, plasticity and increased ductility.

Elements:

- PVA glue – 90 ml (or 5 tbsp.);

- cold water (1 tbsp);

- body lotion (0.5 tsp);

- starch – 20 g (2-3 tsp);

- shaving foam (6 tbsp);

- food coloring;

- a few drops of sodium tetraborate.

Step-by-step instructions:

- Combine glue and water in a container.

- Add gel lotion.

- Add starch and mix until smooth.

- Distribute shaving foam evenly over the mixture and stir.

- Add brightness with paint.

- Add sodium tetraborate, working vigorously with a spatula.

- Add by hand if the jelly is sticky.

Adjusting the amount of borax and starch makes it possible to control the thickness, stickiness and stretch of the slime.

Lush fluffy

It turns out that you can make your own jelly, no worse than the store-bought equivalent. Fluffy, bubbly, stretchy slime with sodium tetraborate and shaving gel that thickens the structure is easy and simple to make. The main thing is not to overdo it with the amount of activator, introducing it in doses.

Ingredients:

- PVA glue (3 tbsp.);

- shaving gel (1.5 tsp);

- high fat cream (0.5 tsp);

- shampoo (0.5 tsp);

- one ball of toothpaste;

- sodium tetraborate solution (a few drops);

- gouache or other paint.

How to cook:

- Mix glue and shaving gel in a convenient bowl.

- Pour in cream and shampoo.

- Squeeze out the paste and stir with a spoon until smooth.

- Add sodium tetraborate and bring until thick.

- Knead the substance thoroughly with your hands.

- Add dye and knead again.

In 1984, the cartoon “Ghostbusters” was released, where the main character was a cute ghost that stuck to the surface and became the prototype of the viscous mass. Since then, every child has dreamed of a neon toy, slimy at first glance, but very funny, released in the wake of the popularity of the animated series.

Advantages and disadvantages of the product

Let's start with the pros:

- The drug is extremely affordable. The cost of a bottle of borax does not exceed $1, which is several times cheaper than other antiseptics and combination products.

- The drug is non-toxic, well tolerated and does not cause serious side effects.

- The product can be used in problem categories of patients: children, pregnant women, nursing mothers.

- The drug is effective, especially in gynecology. Glycerin has a softening and anti-inflammatory effect, relieving itching and burning, and boric acid helps restore the acidic protective environment of the vagina, stimulating the growth and reproduction of beneficial lactic acid bacteria.

Butter slime with plasticine

A distinctive feature of “butter” chewing gum for hands is its extraordinary softness, which makes it possible to compare their texture with butter that is spread on a bun. Properly made slime should not stick to your hands or any surfaces.

What to stock up on:

- PVA glue (55 ml);

- water (0.5 tsp);

- liquid soap (2 tsp) or shower gel;

- sodium tetraborate (a few drops);

- a plate of air plasticine.

To obtain a black color, you can add clay of this color. Red, yellow, green chewing gum is made using acrylic paints.

Process:

- Shake the glue and water with a spatula.

- Pour soap and stir.

- Add sodium tetraborate and beat until stiff.

- When the jelly does not stick to your hands, add softened plasticine portionwise and mix evenly.

The mass must have a homogeneous structure, not tearing, not smearing on the surface. Just adding 2 drops of shower gel will remove excess stickiness.

Side effects

A side effect to the drug can only appear if there is a high sensitivity to the components.

These include:

- Itching

- Weakness

- Possible skin rashes

- Convulsions

- Digestive disorders

- Dermatitis

- Failure of the menstrual cycle

- Abdominal pain

- Cardiopalmus

- Anemia

You should stop using this drug if you experience any side effects and seek immediate medical attention.

Contraindications

- Mechanical damage to the skin and mucous membrane

- Breastfeeding and pregnancy

- Hypersensitivity to individual components of the drug component

- Drug intolerance

Inedible marshmallows

Slime made from sodium tetraborate with the addition of toothpaste is airy and quite voluminous, comparable to sweet marshmallows. It stretches and springs well.

What's included:

- PVA glue – 55 g (or 3 tbsp.);

- toothpaste (2 tbsp.);

- shampoo (2 tbsp.);

- thickener (about 7 drops);

- liquid dyes – 2 shades.

Preparation method:

- In a bowl, combine toothpaste and shampoo.

- Beat with a whisk until fluffy.

- Stir thoroughly, adding glue.

- Pour in the thickener, in this recipe it is sodium tetraborate, and bring the mass to density.

- Divide into two equal parts and paint both.

- Connect them into one whole.

It is the paste and shampoo that add fluffiness and texture to the product. If you use brightly colored toothpaste, you won’t need paint, and if it’s mint, it will give the slime a pleasant aroma for a while.

Safety rules for making your own

The toy itself is harmless, but when making it, you should follow some safety rules:

- Do not taste the ingredients and be careful that your child does not accidentally eat them while kneading.

- Use utensils unnecessary in everyday life to dilute all the necessary substances to the desired concentration.

- Don't forget to protect your hands and clothing, as you will have to work with different dyes.

See also

Step-by-step instructions on how to make slime from hairspray with your own hands

Festive sparkling glitter slime

This recipe is a worthy addition to the existing interesting ideas for creating slime at home, and the glitter will “refresh” it and save it from mediocrity.

Components:

- transparent stationery glue (30 ml);

- colorless liquid soap (30 ml);

- about 10 drops of sodium tetraborate;

- water (40 ml);

- highlighter cosmetic (3-5 g).

Preparation:

- Mix glue with soap.

- In another container, combine 10 drops of thickener with water.

- Mix both solutions, stirring with a spatula. Once the mass begins to thicken, knead it with your fingers.

- Add powdered highlighter and mix in.

To extend the period of use, you need to put the substance in a container with an airtight lid so that it does not dry out.

Toy storage features

Slime without packaging dries quickly, so you need to store it in an airtight container with a closed lid. This will protect the toy from weathering and ensure its long service life.

As for the storage location, you need to choose something dark, dry and cool. The refrigerator door is best for this. Storage in the freezer is unacceptable: after defrosting, the toy will lose its elasticity.

Slime storage

Slime also doesn’t like moisture, so it needs to be stored in a dry place. As for a store-bought toy, it must be stored in its original packaging.

Sodium tetraborate is not only a drug used in medical practice, but also the main ingredient for creating slimes. When working with borax, you must adhere to safety rules, as well as the recipe for creating slime. The product should also be stored correctly so that it can serve for a long time and delight children.

"Mountain Peaks"

A special type of slime is the alternation of two or more balls, creating the appearance of mountain peaks. The white top layer symbolizes the snow cover, and the bottom layer is transparent, creating a harmonious transition of the color palette. It is important that the shades are combined with each other, since during the game the wrong combination of colors will lead to a sloppy appearance of the slime.

Components for the transparent layer:

- transparent glue (30 ml);

- water (0.5 tsp);

- sodium tetraborate (about 5 drops);

- paints (2 shades).

How to make a transparent layer:

- Pour glue, water into the prepared deep bowl and mix.

- Add the thickener there and thoroughly beat the substance until it comes off the walls of the container.

- Continue kneading with your hands.

- Divide into 2 halves and paint one in the desired shade.

The transparent toy has a bubbly structure, which adds to its attractiveness.

Ingredients for the white layer:

- PVA glue (4 tbsp.);

- water (1 tsp);

- white liquid soap (3 short sprays or 0.5 tsp);

- hand or body care cream (quarter teaspoon);

- thickener (a few drops).

How to make a white layer:

- Squeeze glue and soap into a container.

- Add cream and water.

- Bring until smooth with the addition of the activator.

- Stir until compacted.

Do not add dye, as this is the snow-white cover of mountain peaks.

How to connect the layers:

- Take a small jar with a lid.

- Place the transparent mass tightly on the bottom.

- Then the colored layer.

- Next, distribute the white ball evenly throughout the jar so that the colored layer does not peek out and compact it thoroughly.

Set the container aside for a day so that the layers are harmoniously connected to each other.

Copper pipe connection

Copper pipelines are expensive. The investment can be justified with careful installation, which is often carried out by capillary soldering using borax as a flux.

It is worth noting that today, other fluxes are sold that are more convenient to use. One pipe is inserted into the second or fitting so that the gap does not exceed 0.4 mm.

Soldering time is short, 3 minutes. It is important that the parts remain stationary during operation. In order for the borax powder to stick to the surface, the copper is first heated with a torch.

For pipes with a diameter of up to 108 mm, the soldering process is carried out at low temperatures not exceeding 450°. The seam is wide (up to 50 mm), but not very strong. Wide pipes with a diameter greater than 159 mm are soldered at high temperatures. Only professionals can perform the procedure.

In both cases, the solder melt penetrates well into the capillaries of the parts, which contributes to the formation of strong connections. It is recommended to remove any remaining borax.

It must be remembered that soldering is accompanied by the formation of smoke, so you can only work in ventilated areas.

Fantastic neon slime glow

Rainbow Slime is easy to find in the dark, it's fun to play with and kids love it. Glowing in the night, it resembles an alien artifact left by aliens on Earth for people to enjoy.

What do you need:

- any glue (100 ml);

- fluorescent powder (available at craft stores).

- sodium tetraborate (can be replaced with a mixture of flour and starch, shampoo and soda);

- acrylic or food paint if the powder does not provide a tint.

Cooking process:

- Pour glue, dye (if necessary) and fluorescent pigment into the prepared container, mix everything.

- Gradually introduce borax drop by drop.

- Knead with a spoon, then by hand.

The finished substance can be white or transparent, but a colored specimen looks more interesting. In daylight, the slime made from glue and sodium tetraborate with glowing powder has one shade, and in the night – another.

Kinds

Based on appearance, welding drills are divided into 2 types.

- Solid. In powder form, flux has the form of solid fine fractions. This shape makes it easy to lay borax on a metal surface before the soldering process, while the substance does not spread. Solid borax is sold in boxes that are sealed, thereby protecting the substance from moisture and the negative influence of the environment. In the powder fraction, borax is white.

- Divorced. This type of borax is considered the most suitable for light metal and its alloy. The substance is the same powdered borax, but dissolved in a liquid. This feature of the flux makes it possible to use it at low soldering temperatures. Using diluted borax is quite simple: small metal elements are dipped into it and then soldered. This flux is popular in jewelry, as well as when working with wires and contacts.

Glossy slime

A plastic, soft, highly stretchable substance is the result of a tandem of types of glue and a solution of sodium tetraborate in glycerin.

Components:

- PVA glue (55 ml);

- stationery glue (30 ml);

- thickener solution (sodium tetraborate);

- decorative elements (foam balls, glitter or sprinkles).

How to cook at home:

- Combine both glues.

- Add the solution drop by drop, stirring with a spoon.

- Take it in your hands and knead until the lumps disappear completely.

- Color it to your liking with the addition of sprinkles or balloons.

Authenticity

Qualitative reaction. To 5 ml of a 4% solution add 0.1 ml of a 0.1% phenolphthalein solution; the solution turns red. When adding 5 ml of glycerin, the 85% solution should become colorless.

- Qualitative reaction. To 0.2 g of the substance add 1 ml of concentrated sulfuric acid, 3 ml of 96% alcohol and mix. When ignited, the mixture should burn with a green-edged flame.

- Qualitative reaction. A 4% solution should give a characteristic reaction A to sodium (General Pharmacopoeia Monograph “General reactions to authenticity”).

Sand handgam

A trip to the seaside with children is a reason for experimentation. Sand is an excellent material for a jelly-like product, and beautiful pebbles will add originality to the slime. You can play with it on vacation and bring home a toy that smells of sea air.

What you will need:

- stationery glue (50 ml);

- water (2 tbsp);

- regular or kinetic sand (necessarily clean);

- a few drops of sodium tetraborate.

Step-by-step instruction:

- Combine the glue with water, adding sand gradually 0.5 teaspoon at a time until the mass is sticky and soft.

- Add sodium tetraborate (3 drops), stirring with a stick, bring to the desired viscosity.

- Stretch with your hands.

- Decorate with beach decor.

A new slime will give you many pleasant moments of leisure, and working together as a family on a craft will charge you with team spirit and bring you together.

From Vaseline

The material is used as an auxiliary ingredient, since it is not suitable for the base and activator, but provides volume, stretchability and clicking sounds during playing.

Compound:

- glass of water (200 ml);

- a small jar of Vaseline;

- adhesive base (3 tubes);

- a few drops of sodium tetraborate;

- coloring and flavoring optional.

Proven method:

- Add Vaseline to the water and stir to dissolve as much as possible. To make the task easier, you can heat the mixture in the microwave for 30 seconds.

- Pour in paint, flavor (optional), glue and stir.

- Inject the activator in doses, working with a spatula until it becomes elastic.

Properly made jelly can be tested by pouring it onto the table: it should not drain from the surface.

Scope of application of the drill

Sodium tetraborate has been actively used for the following purposes:

- as a flux during soldering and melting of metals;

- in analytical chemistry studies as a standard substance for determining the level of acid in a solution. Borax is also used to establish the characteristics of metal oxides;

- widespread use in the creation of glazes, enamel, glasses for optical instruments and decoration;

- the powder is used in pharmaceuticals and paper production;

- is a natural preservative and means for disinfection and control of parasites;

- is a component in the chemical industry to create household cleaning products;

- relevant application in the creation of cosmetic products;

- borax is used as a base for creating boron;

- the substance is a component for creating insulating building materials;

- in light industry, sodium tetraborate is applied to the product before the painting procedure.

Using a drill in everyday life

Borax can be found in most grocery stores. It is a relatively inexpensive product, making it an excellent choice for many household projects.

Use of sodium tetraborate as a medicine

The substance is very effective in controlling pests: cockroaches, ants and other household insects. The mixture is ready by mixing equal parts of powder with sugar. Sugar helps attract beetles and borax exerts its detrimental effect on the insect. It is recommended to keep the substance in hard-to-reach places, away from pets and children. Optimal places: under stoves, refrigerator and sink. Borax also works well against mice. You just have to apply the powder in the areas where the mice are located, and the borax will rid you of the pests. You can also sprinkle the solution on the carpet and vacuum it to eliminate the presence of fleas or treat the mattress to get rid of bedbugs.

Borax will get rid of rust. Mixing 1 cup of powder with 2 cups of water and 1 tablespoon of lemon juice makes an effective anti-corrosion agent. The paste-like solution is applied to the rusty items for about 15 minutes. After which the rust can be easily removed by mechanical friction.

Sodium tetraborate is a universal cleaner. Two tablespoons of borax are mixed with 2 cups of water to create an all-purpose cleaner. The solution can be applied in a spray bottle and used to clean kitchen surfaces and bathroom tiles and ceramics. Borax is great for removing very stubborn stains. Borax will help remove stubborn stains from the floor.

Borax will allow you to flush your home plumbing fixtures. Simply place ½ cup of borax into the drain with a few cups of warm water. Borax breaks down dirt that gets stuck in pipes. This will not only remove excess and unclog the drain, but also disinfect the system.

Application in forging and forge welding

Borax is actively used as a flux for forging and forge welding. The powder is a source of boron oxide, with excellent antioxidant properties. Borax can, if necessary, remove small cracks during metal processing, change the shape of a product, or when heated during artistic forging and blacksmithing of metal. The substance is classified as a high temperature flux. The processed workpiece with borax is characterized by more wear-resistant characteristics and durability.

Using borax in soldering.

During the melting of borax at a temperature of 700-900 °C, the surface of the material being processed is cleaned, and all excess inclusions are dissolved in the flux. During the processing of a material by forging, a thick layer of scale is gradually created. In some cases, the metal being processed may completely burn due to overheating of the part. But by using a thin layer of borax, this scenario can be avoided.

In industry

Industrial enterprises find the following uses for this substance:

- as a raw material for the production of boric acid;

- as an antiseptic in the production of bulk insulation materials such as “Ecowool”.

- as a means for determining the concentration of acid solutions;

- in welding production as a component of flux;

- in the mechanical engineering industry as a component of antifreeze and various lubricants;

- in glass production;

- the fabric is treated with sodium tetraborate for better dyeing;

- Borax is a component of almost all cosmetic products.

Using borax in the soldering process

In addition to household use, borax is a popular raw material for soldering. High temperature flux is produced as a finely dispersed powder. When heated above 700 degrees Celsius, the flux flows into a liquid state and becomes solder. I’ll tell you about the pros and cons of this flux in the table below.

| Pros of borax flux | Cons of solder |

| The elements being connected do not need to be heated to the same temperature. | After the borax solder cools, salt-type deposits form on the surface of the seam, which will have to be cleaned off from time to time. This is not very convenient for hard-to-reach places. |

| The quality of the roller is high even when connecting different materials. For example, metal and non-metal. | |

| The roller can be destroyed if necessary by reheating the borax to the melting point. | |

| The peak heating temperature of 700+ C will not allow copper parts to warp + the characteristics of the weld with this solder are higher than usual. | Flux absorbs moisture very well. A closed storage container doesn't even help. Too wet solder reduces the quality of the roller several times. |

| Capillary soldering itself is considered the best solution for connecting small and medium-sized parts. | |

| The powder mixture makes it possible to achieve a high level of seam strength. |

To learn how to use Borax without jambs, you need to maintain clear proportions when applying. For beginners in welding, this can be problematic, so gaining practical experience with such solder is extremely important.

Rules for soldering with technical borax:

- The base for applying boron powder must first be cleaned. The welder gets rid of various greasy stains, wax and other debris from the surface of the future seam. For this procedure I use regular sandpaper. It's quite enough.

- The soldering iron tip needs to be preheated before touching the solder.

- To form a reference seam, I advise you to heat the workpieces to the same temperature.

- The tip of the soldering iron should heat both sides of the elements being connected.

- Do not skimp on solder to form a quality connection.

- When the solder begins to flow, the soldering iron tip is temporarily removed from the joint location.

- After applying the bead, the joined elements cannot be moved until they have completely cooled. When working with transistor components, you should use “crocodiles” that will act as heat sinks, thereby reducing the risk of temperature damage to the filling.

If dry joints occur, the roller must be melted and the seam redone. After finishing work with solder, the tip of the soldering iron is cleaned. When working with copper parts, cleaning the edges of the elements being joined is especially important.

What tools and materials are used in the borax soldering process:

- soldering iron Used to heat solder + sometimes for the connections themselves. Sometimes it is more convenient to heat the elements with a gas burner;

- stand. To position the soldering iron while it is heating up or is inactive. There are a lot of variations of stands for this instrument on the Internet, so choosing one that is convenient for you will not be any problem;

- rag or sponge. Consumables needed to clean the soldering iron tip;

- fine grit sandpaper. Used for stripping joints to which solder will be applied;

- crocodiles. The clamps play an auxiliary role as radiators;

- burner. Needed when soldering pipes.

Also, to improve the quality of the seam, I advise you to use boron flux, which will contain fluoride or chloride elements. When soldering pipes, the elements being connected must be heated for at least 25 seconds.

How to make borax with your own hands?