The purpose of a diagnostic cast is to create a model of the dentition. Not all the necessary information can be obtained by examining the oral cavity. The model will allow the dentist to understand and take into account the individual characteristics of the position of the teeth, dental arches, possible anomalies (for example, diastema - a gap between the teeth, etc.), tissue relief and much more.

Once the impression is received, it is sent to the laboratory, filled with plaster and a diagnostic three-dimensional model is obtained, usually of both jaws. Both jaw models are installed in a special device (articulator), which simulates the movements of the jaws during chewing.

The diagnostic model is useful when communicating between a doctor and a patient, because you can clearly demonstrate existing problems and jointly discuss a way out of the situation. Using the model, you can explain to the patient the validity of a particular decision made by a doctor. You cannot do without a diagnostic model when correcting your bite or making prosthetics.

Composition and properties of the mass

The basic component of the material is sodium alginates, whose structural content resembles salts of alginate acid.

To form impression material used in dental practice, the drug is produced in a powdery consistency with a fine texture . If you mix it with water, you get a paste-like mass.

Depending on the declared properties and performance characteristics, materials are classified into three main groups:

- multicomponent powder mixtures - in combination with a solution of sodium alginate, taken in a 5% concentration. In the process of their interaction, a flexible, highly plastic mass is obtained;

- It is produced both in the form of powders and pastes . The best representative is Algelast - 66, widely used by domestic clinics;

- the most complex composition - has a unique composition and, when it comes into contact with a liquid medium, forms a soft, plastic impression paste. It is produced in a wide range by Russian pharmacological enterprises. The most popular brands are Stomalgin - 66, Novalgin.

All presented options are distinguished by their ability to harden at room temperatures.

The use of impression mass requires its immediate casting, since at the moment the model is removed from the oral cavity, a liquid medium begins to form on its surface part, prone to peeling.

It contains acidic components, and these, in turn, prevent the gypsum from hardening and soften its surface.

To prevent this from happening, immediately after removal, the material is washed well with running water, and then treated with a special gypsum hardening accelerator.

Impression materials

The impression mass must satisfy the following requirements: give an accurate impression of the prosthetic bed; be harmless and not have an unpleasant odor or taste; easy to enter and remove from the oral cavity; do not become deformed when removed from the oral cavity; do not dissolve under the influence of saliva; soften at a temperature that does not cause burns to the oral mucosa; harden for 2-5 minutes; do not connect to the model plaster and are easily separated from it; be stored at room temperature without losing its properties.

Crystallizing (hard) impression masses . Solid impression masses include gypsum, zinc-eugenol masses, Dentol-M, Dentol-S. Currently, gypsum is practically not used in dental practice for making impressions due to its non-plasticity, traumatic nature, fragility, and poor biocompatibility with oral tissues. Zinc-oxyeugenol impression materials contain zinc oxide, eugenol, filler, structuring accelerator, rosin, balsam, plasticizer, and dyes. Impression materials of this group are produced in the form of two separately stored pastes, one of which contains eugenol (or gualcol), the other – zinc oxide. Structuring occurs when zinc oxide reacts with eugenol (when two pastes are mixed). This material gives minimal shrinkage, is durable, and highly plastic. It is mainly used for taking impressions of toothless jaws. Thermoplastic impression compounds . A feature of thermoplastic impression compounds is that they soften and harden only under the influence of temperature. They soften when heated and harden when cooled. Thermoplastic masses are multicomponent systems based on natural or synthetic resins, filler, modifying additives, plasticizer and dyes. This group primarily includes wax, as well as gutta-percha. Thermal masses should soften at a temperature that does not cause burns to the tissues of the oral cavity, and harden at a temperature slightly higher than the temperature of the oral cavity. These include Weinstein masses, Kerr masses, Orthocor, Stomaplast, Dentafol, etc.

Elastic impression materials . Elastic impression compounds include a large group of different substances, the characteristic feature of which is the ability to acquire elastic, elastic properties as a result of structuring. Based on agar-agar (a product obtained from some agarophyte seaweed), 2 groups of elastic materials have been developed: hydrocolloid and alginate.

Alginate impression masses contain a main component – sodium alginate (sodium salt of alginate acid). These are: Algelast-66 (paste powder), Stomalgin-66 (powder), Novalgin (powder), Orthoprint, Hydragum, Dupaflex, Tricoloralgin, Palgaflex, Propalgin, etc. The advantages of alginate masses include: high elasticity and hardness, good reproduction relief of hard and soft tissues of the oral cavity, ease of use, absence of unpleasant odor, good tolerance by patients. Working models from these masses are obtained in the manufacture of complete and partial dentures. However, alginate masses are not used for cellite structures due to the unsatisfactory accuracy of displaying the cervical and subgingival areas, as well as the high shrinkage of these materials. In addition, it is advisable to cast models using alginate impressions within 10-15 minutes (due to high shrinkage), which is not always convenient.

Silicone (rubber-like) impression materials . Currently, in the dental practice of dental prosthetics, silicone masses based on organosilicon polymers - silicone rubbers - are increasingly used. They are produced as a set in the form of pastes and liquid catalysts, when mixed, vulcanization occurs within a few minutes and an elastic product is formed that does not lose its properties for a long time. Based on the type of vulcanization, silicone masses are divided into C- and A-silicones. C-silicones harden under the influence of a polycondensation reaction. Materials of this class are subject to fairly strong shrinkage (less, however, than that of alginate masses) due to the formation of by-products - alcohol and water. Models based on impressions from C-silicone are cast in 1-2 hours. A-silicones cure through a polymerization reaction that produces virtually no byproducts. Models based on them can be cast without loss of quality within a period of up to a month, but preferably within a week. The disadvantages of this type of materials include their lack of good adhesion to impression trays. One of the most commonly used silicone materials is Sielast-69. Its vulcanization (hardening) time in the oral cavity is 4-5 minutes. The materials Sielast-0.3 and Sielast-0.5 are intended for taking double impressions, for which they include the main and corrective pastes and a liquid catalyst. Silicone pastes Exaflex (Japan), Coltex + Coltoflex (Switzerland), Dentaflex (Czech Republic), Tsafo-Tevezil, DL-Knet, Panasil, Formasil II, Alfasil, Gammasil, Deguflex (Germany), etc. are widely used.

Our clinics use only advanced methods of treating and diagnosing oral problems. We are waiting for you!

Curing process and curing reaction

In the process of interaction with water of the powder mixture, a chemically active reaction begins, the result of which is strong transverse adhesion of polymer chains and the formation of an impact-resistant, three-dimensional structure.

Such connections cannot be broken by trying to redirect the structure to its original linear state.

Consequently, these hardening processes can be classified as irreversible, and this drug can be used once and only according to a sequential scheme: mixture - gel mass - chemical processes.

The curing reaction proceeds as follows . Calcium sulfate dihydrate supplies calcium ion elements for cross-linking processes , due to which the sol is transformed into a gel consistency. The ions begin to be partially released from the aqueous base.

The working period and time frame for final hardening of the composition are determined by the rate of formation of ions and their tendency to form transversely.

Accelerated dissolution of sulfate substances could produce a composition unsuitable for working hours. To prevent these phenomena, sodium phosphate was introduced into the drug component . It has a sedative effect on the explosive primary rate of formation of calcium ions.

In such a situation, phosphate performs an inhibitory function ; its concentration can regulate the hardening speed and modify the impression material.

The processes of bringing products into a solid state entail a change in the acidic background in the oral cavity.

As it hardens, this indicator drops, which helps to give a visual assessment of the action of the described processes and allows you to regulate the time of dental work with the material .

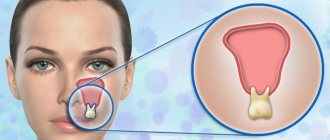

Taking a diagnostic impression

The oral cavity must be prepared

Having agreed with the patient on the type of prosthesis, selecting the materials for the impression and the necessary tools, the prosthetist begins the procedure of taking the impression. It begins with an examination of the oral cavity and determining whether individual teeth require extraction or treatment.

If there are bone growths (exostoses) in the place of the former lateral chewing teeth, the doctor will have to remove them. The oral cavity is thoroughly dried with cotton swabs or a special dental gun. Now it’s time to start selecting a spoon, an instrument with which the impression mass is introduced into the oral cavity.

Spoon selection

Selecting a tray is an important step as there are several types of impression trays. They differ:

- Size . For jaws and dentition of different lengths, sizes and shapes, teeth of different heights, a suitable spoon is required. A standard set of spoons is not suitable in all cases. Sometimes you have to make a spoon individually.

- Material. Spoons come in metal and plastic, with different hardnesses.

- By appointment . A special tray is used to take an impression of the lower or upper jaw.

- A type of cast . Separate trays are provided for compression and decompression (without pressure on the gum) impressions.

Preparing the impression material, applying the material to the tray and taking the impression

Having selected the correct spoon, the prosthetist begins mixing the impression mass.

The prepared mass is placed on a spoon, then, using a spoon, into the oral cavity.

The spoon is positioned and pressed first in the area of the chewing teeth, then in the frontal teeth.

Without waiting for hardening, the prosthetist removes the spoon from the mouth very carefully so as not to damage the impression.

Two-stage and one-stage method of taking an impression

With the two-stage method, the impression is made in two steps. First, the main impression material is introduced, the first impression is made, and dried. Then a corrective composition is applied to it and the impression is made again. The one-step method involves simultaneous application of the main mass and the corrective composition to the spoon. The finished impression remains to be washed, disinfected and sent to the denture laboratory for the production of a diagnostic model.

Instructions for use

Instructions for using the product include several main steps:

- mixing plaster – the material can be mixed manually yourself, or you can use a vacuum mixer. All instruments must be cleaned of foreign impurities.

Particles of gypsum remaining on their working surface from previous manipulations will negatively affect the quality of the surface of the finished structure and activate the hardening processes of the material.It is necessary to ensure that the mixture is homogeneous, similar in thickness to sour cream, and does not contain bubble fragments;

- casting – distribute a small part of the gypsum on the relief surface of the structure, adjacent to the dental units – as a rule, this is the palatal area in the upper jaw or the sublingual areas in the lower area.

After this, carefully tap the cast around the perimeter so that the material is evenly distributed, filling all the voids and pores. If necessary, add another component.It is preferable to work on a vibrating table. If pores do exist, the cast is turned over and the liquid mass is removed into the bowl. The manipulation is repeated from the beginning. If everything is done correctly, form the base frame and turn the model over;

- Removing the mock-up impression is performed after the material has completely hardened.

Since in this state the plaster loses its elasticity, this is quite difficult to do and can damage neighboring teeth. Under no circumstances should you leave a cast that has already been cast for the whole night. When opening, first remove the impression tray, then, gradually loosening the mass, remove the impression itself; - trimming the finished model - achieving a flat base and parallel occlusions. The side parts are carefully cut so as not to disturb the transitional folds and bends.

This is interesting: Parapulpal pins in dentistry - when they are used and how the pins are installed

Impression technology

Most impression materials are supplied in the form of a multicomponent powder that is diluted with water. Mixing is usually done by hand.

Special mixing systems make the work somewhat easier and stabilize the result, but do not significantly improve the quality of the prepared mixture.

Sequence of operations:

- Shake the container with the powder several times to ensure good mixing.

- Pour the required amount of water into the rubber mixing cup (using the measure supplied by the manufacturer). It is recommended to use distilled (demineralized) water.

- Add powder to the water in the exact amount specified in the instructions. When using standard measurements, they are filled flush with the edges, “without a slide.”

- Mix the powder and water thoroughly and vigorously with a plastic spatula. The best way to stir is to rub it along the sides of the cup. Kneading should last strictly for the time specified in the instructions. Usually it is 30-40 seconds.

- Place the mixed mixture into the impression tray. The post layer should not be less than 5 mm thick.

- Insert the spoon into the patient's mouth. If an impression is made of the lower jaw, it is advisable that the mouth be covered. This avoids distortion of tense muscles.

Immediately before inserting the tray, it makes sense to apply a little paste with your finger to the fissures of the chewing teeth and interdental spaces to improve the quality of the impression.The time the paste remains in the patient's mouth is called curing time. It must correspond to the values specified in the instructions and, in addition, be controlled by palpation.

The correct way to do this is with the paste remaining in the cup. Since the outer layers of the mixture in the patient’s mouth usually harden faster than the deeper ones, you cannot focus on them. Premature removal of the impression from the oral cavity will lead to its deformation.

- Remove the finished print. It is very important that when removing the impression, it does not detach from the tray; placing it back will be extremely difficult.

To do this, you need to remove the impression by grasping it with your fingers, and not pulling it out by the spoon. The best method of removal is by pressing on the impression in the lateral areas of the vestibule of the mouth.If there are areas on the jaw with and without teeth, you need to press on the impression in the area of the teeth - in the direction of their axis. You need to remove it with a fairly sharp movement to avoid residual deformation.

- Clean and check the impression. Traces of saliva and blood are washed away with a stream of running water. The print is checked for air bubbles and print quality. It is advisable to trim off excess material around the edges of the spoon.

- Disinfect the impression. It is carried out by treating it with a disinfectant solution, which can be used as iodizole in a ratio of 1:10 with water or sodium hypochlorite. Disinfection occurs in a few minutes, and the dimensions of the impression do not change critically.

This is interesting: Using Corega brand denture cleaning tablets

The impression should be filled with plaster as quickly as possible, ideally in the first half hour after its removal. If you need to transport it, you need to place the impression in a plastic bag with a piece of a damp cloth.

But it should not touch the cast, otherwise it will become saturated with water and swell. In an environment with 100% humidity, a print can be stored without significant loss of quality for about a day.

The video provides additional material on the topic of the article.

Medical Internet conferences

Comparative characteristics of modern alginate and C - silicone impression masses

Belyankin I.A., Afanasyeva M.M., Aslanyan M.A.

Heads: assistant of the department Nelovko T.V., head of the department Eremin O.V.

FSBEI HE "Saratov State Medical University named after. V.I. Razumovsky" of the Ministry of Health of Russia

Department of Propaedeutics of Dental Diseases

Modern dentists are faced with choosing the most appropriate impression mass.

Purpose : to explore and compare the properties and purposes of modern alginate and C-silicone impression masses.

Materials and methods : 1) Alginates are a fine multicomponent powder that must be thoroughly mixed with water, rubbing against the walls of the rubber container for 40 seconds, hardens in 2-3 minutes. (Ypeen).

2) C - silicones: the base is a container with a mass and a hardener in a tube; a large tube with a correction mass and a second one with a catalyst. The base is intensively mixed with your fingertips until homogeneity is achieved for 30 seconds, the corrective is mixed on a notepad 1:1; hardens - 2.5-5 minutes. (Speedex).

Results: The alginate mass has a viscous consistency. Accurately reproduces the microrelief of oral tissues, but is inferior to C-silicones.

Advantages of alginate masses: Low cost; ease of use; acceptable accuracy of cast relief for removable dentures and temporary crowns.

Cons: Insufficient accuracy for solid-cast and metal-ceramic structures; strong and rapid shrinkage (after 15-20 minutes 1.5%); the need for immediate casting of the model; poor adhesion to the spoon.

Pros of C - silicone masses: Reasonable cost; sufficient accuracy for solid-cast and metal-ceramic structures, silicone keys; low shrinkage (after 1-3 days 0.1-0.5%); elasticity and strength; admissibility of disinfection; Possibility of casting models in 2 days.

Cons: Difficulty in accurately dosing the catalyst; single use of the impression; hygroscopicity; low hydrophilicity; insufficient adhesion to the spoon; the possibility of allergies; the need for manual mixing.

Conclusion: Alginate and C-silicone impression masses are widely used in modern orthopedic and therapeutic dentistry. Based on the analysis of the parameters, alginate masses are more suitable for the auxiliary jaw, and silicone ones for the working jaw. The properties of alginates are inferior to C-silicone materials.

special instructions

Mixing materials is a very important step in taking an impression.

- It is necessary to strictly observe the ratio of components specified in the instructions. Ignoring this requirement will lead to a violation of the consistency of the impression mass and, as a consequence, to a poor-quality impression.

- To measure powder and water, use the dosing containers included in the package.

- The mixing times indicated in the instructions assume the use of distilled water at a temperature of approximately 23 °C . If hard water or higher temperatures are used, the processing time should be reduced.

Advantages and disadvantages

The advantages of the drug include:

- high strength combined with mass elasticity;

- different range of material adhesion , which allows you to choose the product that is most suitable in each specific situation;

- high stability of initial parameters;

- rapid absorption of liquid>;

- ease of mixing the components of the product;

- minimal content of dust fragments , which eliminates the risk of inhaling dust pieces during the manipulation process;

- long shelf life in closed packaging - at least 5 years from the date of manufacture;

- a special composition that minimizes the risk of subsequent shrinkage of the mixture after hardening;

- does not spread in the patient’s mouth;

- has a pleasant taste and does not irritate soft mucous tissues;

- all substances included in the drug are made from natural ingredients and are safe for human health;

Allergic reactions of the body are a phenomenon that is isolated in nature and is classified as an exception.

Alginate-containing powders also have disadvantages:

- too large a proportion of water in the composition is fraught with long processes of hardening of the mixture;

- excessively rapid dissolution of the mass can, on the contrary, accelerate these processes;

- if the composition is kneaded without observing the technology and the required proportions, then over time it will begin to crumble;

- any discrepancy with the instructions for use will lead to a violation of the structural content of the material and a violation of its integrity in the shortest possible time.

Alginate for impressions: the best offer for dentists

In order to make a high-quality impression, alginate masses are used in dentistry - special masses that have plasticity and elasticity. This material is used to take impressions for prosthetics and bite correction.

Today, doctors have access to new impression materials that have a number of advantages. But most doctors continue to use alginates in their work - convenient, practical, inexpensive masses for making impressions. Alginate mass for impressions does not require special conditions for use; it is much easier to work with than innovative silicone fillers. An important advantage of alginates is their natural origin. The raw material for the production of this impression mass is seaweed.

Among the important advantages of alginate impression masses, the following should be noted:

- holds its shape well;

- tools do not stick to the substance.

Alginate impression mass is one of the most used materials and not every doctor can afford to buy it at a high price. Given the high consumption of material, every specialist strives to buy good, high-quality raw materials for impressions at a lower price. Today you can do this in the All4dental online store. We do not work with intermediaries and offer you high-quality materials at a price significantly lower than the cost of similar products at offline points of sale.

Diagnostic dental cast: materials and varieties

Materials

To obtain a diagnostic impression of teeth, medical plaster and more modern plastic materials (thermoplastic and elastic masses) are used, which are able to acquire the shape of the dentition and maintain it.

All materials from which the impressions are made do not cause allergies. They are divided into several types:

- Hard (gypsum, dentol). They reproduce the texture of fabrics well, are easy to use, but are excessively rigid. Because of this, imprints of areas of the tooth located closer to the gum are not always successful.

- Elastic (silicone, alginate, etc.). To enhance the strength of the impression mass, special fillers are added to it. When heated, such an impression mass becomes softer and recreates the contours of tissues well. Disadvantage: elastic impressions are not suitable for long-term storage, unlike hard ones. For example, silicone impressions shrink within 3 hours after the impression. The model must be manufactured strictly within this period of time.

- Thermoplastic (gutta-percha, Kerr mass). The material becomes plastic when heated and hardens after cooling. Advantages of this type of casts:

- good separation from plaster during model making;

- Possibility of repeated administration into the oral cavity.

Types of diagnostic casts

Compression diagnostic casts . Made for the lower jaw. Purpose - to determine the distribution of load during chewing for the future prosthesis. Requires materials of high viscosity.

Unloading . They are used in the preparation of prosthetics for people whose activities are related to oral speech. When chewing, the load will be distributed unevenly.

Combined . With their help, dentures are made that evenly distribute the load both during eating and when talking.

Properties of alginate impression mass

Viscosity

Alnate impression material is quite viscous, but this directly depends on whether the paste is mixed in the correct proportion. It is very important to adhere to the correct proportions to achieve optimal viscosity.

Accuracy

The accuracy with which the alginate impression mass transfers small objects reaches a maximum of 50 m. This is somewhat less than that of silicone impression materials, so alginates are not recommended for use when taking impressions for working models that require particularly high precision.

Elasticity

The elasticity of the alginate material is such that it can be used to image undercut areas. However, its elasticity is several times less than that of other impression masses, for example, hydrocolloid ones. Alginate material collapses even at 50% pressure and at fairly low tensile loads.

How to work with the material to make an impression?

Of course, you can make a cast yourself. But it is not recommended to use it to form a prosthesis, since a person without special training is unlikely to be able to make an accurate impression of the required part of the jaw.

Algorithm of actions:

- Selecting a spoon for applying the mixture, which are divided into groups (universal and special, plastic and metal). It is better to use metal ones. This ensures that they will not become deformed while the material is being applied to the patient's teeth. You also need to pay attention to the size of the spoon. It is desirable to have thickened sides with a total width of 5 mm larger than the tooth.

- The choice of the type of alginate mass depends on the scale of the work, as well as the degree of damage to the jaw.

- The mixture is prepared in strict accordance with the instructions. The ingredients are distributed using measuring containers. Incorrect use of materials will affect the hardening time of the mass, as well as its ductility. When kneading, use a rubber bowl.

- Applying the mass. An impression is made not only of the jaw where the prosthesis will be installed, but also of the opposite side. The material is also applied to adjacent teeth in order to calculate the distance between the teeth and the maximum size of the future prosthesis. For the upper jaw, the inner part of the tooth is covered first, and for the lower jaw, the outer part is covered.

- Removing the finished print is done in one strong movement to prevent deformation.

Alginate impression mass, ready-made impressions

It is best to use the impression to make a prosthesis during the first 30 minutes. But if transportation is necessary, the impression is wrapped in a damp cloth and placed in a plastic case.