Composition and main types of adhesives

Adhesive properties of adhesives

Influence of characteristics of labeled materials on adhesion

Influence of label application conditions on adhesion

Influence on adhesion of the conditions of transportation, storage and consumption of goods with an applied label

Theories of adhesion and bonding

The strength and durability of the adhesive joint depend on the strength of the adhesive layer and the materials being glued, as well as on the strength of the so-called adhesive seam. There are several theories of adhesion and bonding that explain the formation of an adhesive seam in different ways. To describe the processes that occur during labeling, mechanical and molecular theories are probably of greatest interest.

Molecular theory

According to molecular theory, adhesion is a process caused by the adsorption of glue molecule units by the surface of the material. The formation of an adhesive seam occurs as a result of the migration of large adhesive molecules to the surface of the material and the subsequent formation of a chemical adsorption compound under the influence of intermolecular attractive forces.

According to this theory, high adhesion is possible when the polarities of the adhesive and the material match, otherwise adhesion is difficult.

Literature:

Vorobiev D.V. Technology of post-printing processes. M.: MGUP, 2000.

Tests to evaluate the parameters of the adhesive layer

FINAT (International Association of Self-Adhesive Industries) has developed a series of FTM (FINAT Test Method) tests to evaluate various parameters of self-adhesive materials. Here is a description of tests that allow us to evaluate the parameters of the adhesive layer.

The FTM 1 and FTM 2 tests are designed to evaluate the adhesive strength of the adhesive layer when gluing a label to a product or its packaging.

To perform the tests, acclimatized* strips of self-adhesive material, 25 mm wide and approximately 175 mm long, are separated from the base and glued to a glass test plate, and then rolled onto it with an elastic roller. Measurements are taken after 20 minutes and after 24 hours (to assess final adhesion). When performing tests, it is recommended to use a tensile strength tester or similar devices. Adhesion force is measured in newtons.

According to the FTM 1 test, the strip of self-adhesive material is separated at an angle of 180? at a speed of 300 mm/min, when performing the FTM 2 test, the strip is separated at an angle of 90° at the same speed. Measurements are taken when separating the middle part of the strip. It is recommended to take a minimum of five measurements at 2 s intervals.

The tests described allow comparison of the adhesion of different self-adhesive materials, especially with removable adhesives (paper materials with permanent adhesives are likely to tear when subjected to such a test). The FTM 2 test allows for a more accurate assessment of adhesive adhesion, since when separating a strip of material at an angle of 180? The elastic forces of the label material have a significant impact on the measurement results.

In order to test the adhesion of self-adhesive material to real labeling materials, these tests can be easily modified.

The FTM 3 and FTM 4 tests measure the force required to separate a label from its liner. Before starting the test, strips of self-adhesive material with a width of 50 mm (FTM 3) or 25 mm (FTM 4) are kept for 20 hours at a pressure of 6.86 kPa (70 g/cm2), after which they must be acclimatized for at least 4 hours . The adhesion force of the label to the substrate is measured in centinewtons.

When performing tests, does the strip of facial material separate at an angle of 180°? from the substrate. The FTM 3 test simulates the process of label separation at a speed of 300 mm/min, the FTM 4 test at a speed of 10-300 m/min (label separation in high-performance labeling lines). When performing the FTM 3 test, it is recommended to take a minimum of five measurements at 2 s intervals. For the FTM 4 test, it is recommended to use a device that allows you to record label peel force values with high resolution.

The FTM 8 test allows you to evaluate the cohesion of the adhesive layer. When performing the test, the upper end of a strip of facing material, approximately 175 mm long, is glued onto a vertically mounted glass test plate and then rolled onto it with an elastic roller. The size of the glued area is 25x25 mm. 5-10 minutes after this, a load weighing 1 kg is suspended from the free lower end of the strip and the time during which the strip will be held on the plate is noted. It is recommended to carry out at least three tests.

The FTM 9 test allows you to evaluate the initial adhesion of the adhesive when gluing the label. When performing the test, a tensile strength tester or similar equipment should be used. The ends of a strip of facing material about 175 mm long and 25 mm wide with an adhesive layer facing outward are fixed in the upper movable mount of the device so that the strip forms a loop. A test glass plate measuring 25x30 mm is fixedly fixed at the bottom. During the test, the strip is lowered towards the plate at a speed of 300 mm/min, immediately after the contact area reaches its maximum size, the strip is raised and adhesion is measured. Adhesion force is measured in newtons.

Storing self-adhesive materials

Optimal climatic conditions for storing self-adhesive materials:

- temperature - 20-22? C;

- relative humidity - 40-60%.

To protect materials from changes in humidity, it is recommended to store them in their original packaging and unpack only before processing (after acclimatization). During storage, the self-adhesive should be protected from exposure to direct sunlight; it is not recommended to install heating devices near the pallets.

Rolls should be stored in a vertical position - on the end side, sheet materials - in a horizontal position.

Before processing, the self-adhesive should be acclimatized in the production area for 24-48 hours. This will help avoid warping of the material as a result of sudden changes in humidity.

Adhesive (glue) is an important component of self-adhesive material. The adhesive layer ensures reliable fastening of the label to the surface of the product or its packaging. The variety of materials on which labels are applied determines the large number of adhesives used in self-adhesive materials.

Composition and main types of adhesives

Adhesives are natural or synthetic substances used to join materials by forming an adhesive bond between the adhesive film and the surfaces being bonded.

Based on their physical state (at a temperature of 20°C), adhesives are divided into liquid and solid. Liquid adhesives are most often used in the manufacture of self-adhesive materials. They consist of an adhesive, a solvent or a dispersing medium, and also include various additives that modify the properties of the adhesive. Solid adhesives consist of a hot melt adhesive and additives.

Modern self-adhesive materials use organic adhesives based on acrylic polymers or rubbers.

Acrylic polymers are classified as thermoplastics. They are characterized by very good adhesive properties, light fastness, chemical resistance, stability of properties over time and high transparency. Acrylic polymers are polar, therefore, according to the molecular theory of adhesion (see sidebar “Theories of Adhesion and Bonding”), polar materials, such as glass or polyamide, should bond well.

Natural and synthetic rubbers are characterized by high elasticity and worse light resistance compared to acrylic polymers. Rubbers are non-polar, so they must have high adhesion to non-polar materials, such as polyethylene and polypropylene.

Most adhesives used in modern self-adhesive materials are aqueous dispersions. After applying the adhesive to the substrate, the water evaporates during the drying process. Organic solvents have recently not been included in adhesives due to their environmental hazards.

More recently, UV-curable acrylate adhesives have been developed. The photopolymerizing composition included in their composition is cured under the influence of UV radiation. Acrylate UV adhesives are characterized by the best chemical and physical resistance compared to other types of adhesives.

Rubber hot-melt adhesives are used relatively rarely. The hot-melt adhesive is melted to apply to the substrate. The advantages of such adhesives include good adhesion to wet surfaces, but the disadvantages are low processability of application to the substrate and low resistance to high temperatures.

Adhesives are applied to the canvas by contact or non-contact method, after which the water-dispersion adhesive is thermally dried, the acrylate UV adhesive is cured as a result of irradiation with UV light, and the hot-melt adhesive hardens during the cooling process.

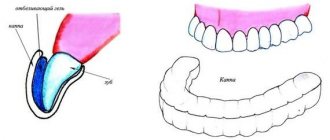

How enamel is etched

This processing method involves removing part of a layer of 10 micronewtons (µN) from the enamel. As a result, pores with a depth of 5–50 μN appear on its surface. Often, for etching, enamel is lubricated with orthophosphoric acid, but for dentin, organic acids can be used, but in low concentrations.

The etching process lasts from 30 to 60 seconds. The individual structural features of the enamel surface, in particular its initial porosity, are of decisive importance. If you overexpose the acid, it will inevitably affect the structure of the enamel and weaken the adhesion. So if the patient’s dental tissues are quite weak, then etching should last no longer than 15 seconds. The acid is removed with a stream of water, and for the same amount of time as it is kept on the enamel.

Adhesive properties of adhesives

The adhesive properties of glue are its main technological and operational characteristics. To evaluate the adhesion value, use test methods developed by FINAT (see sidebar “Tests for evaluating the parameters of the adhesive layer”).

Adhesion of the adhesive to the substrate should allow the label and flash to be separated from the substrate with little force (without tearing), but its magnitude should be sufficient to hold the label until it is forced to separate.

Based on the relative value of adhesion to the labeled material, adhesives are divided into removable and permanent (permanent).

Removable adhesive is characterized by higher adhesion to the label than to the material being labeled, as well as high cohesion. The amount of adhesion of the removable adhesive to the material being labeled must also be consistent with the tensile strength of the label. Thanks to this, it is possible to remove the pasted label without damaging the product or its packaging, the adhesive layer and the label itself. After this, the label can be re-glued onto another product. A label with removable adhesive will adhere to the material being labeled, after which there should be no significant change in adhesion.

Permanent adhesive ensures a stable connection between the label and the surface of the product or its packaging. When you try to remove a label, it usually breaks or the adhesive layer separates. Permanent adhesive is characterized by very high adhesion both to the label material and to the surface of the product or its packaging, as well as high cohesion. When using permanent adhesives, the label gluing process involves two stages: adhesion and curing. During the fixing process, the adhesion of the adhesive to the surface on which the label is applied must reach its maximum value.

When working with high-speed labeling lines, it is very important to be able to quickly correct an error when applying a label. For this purpose, permanent adhesives have been developed, the final fixation of which occurs only a few hours after gluing. Until this time, they act as removable adhesives and allow the label to be removed and reapplied.

The amount of adhesion is influenced by factors determined by the characteristics of the materials being labeled, the conditions for applying the label, the conditions of transportation, storage and consumption of the product with the label applied to it.

How dentin is etched

Japanese dentist Fuzayama was the first in history to use the dentin etching technique 39 years ago. Today, before the procedure, special conditioners are applied to the dental tissues - they help hydrophilic substances penetrate deeper into the dentin tissues and adhere to the water-repellent composite. The smear layer partially disappears, the dentinal tubules open, and mineral salts come out of the upper layer. After this, the conditioners are washed off with water. Next comes the drying stage, and the main thing is not to overdo it, otherwise it will affect the clutch.

Next, a primer is applied, which helps hydrophilic substances pass into the tubules and adhere to the collagen fibers. As a result, a kind of hybrid layer is formed, which contributes to the effective bonding of the composite to dentin. It also serves as a barrier against the penetration of chemicals and microbes into the internal structures of the tooth.

Influence of characteristics of labeled materials on adhesion

Roughness, surface tension and the geometric shape of the labeled material have a significant influence on the amount of adhesion.

High roughness, characteristic of wood, textured paper, cardboard, foam plastics, and fabric, can significantly impair adhesion. If the thickness of the adhesive layer is insignificant, the adhesive covers only the tops of macro-irregularities and does not penetrate into the depressions. As a result, the contact area between the adhesive and the surface on which the label is applied is reduced.

For good adhesion, the surface tension of the adhesive must be lower than the surface tension of the material being labeled. If this condition is not met, it is necessary to increase the surface tension of the labeled material, for example by treating it with a corona discharge. Manufacturers of self-adhesive materials reduce the surface tension of permanent adhesives (especially adhesives based on acrylic polymers) by introducing special additives into their composition. Removable adhesives, on the contrary, must have a high surface tension.

When applied to surfaces of complex shape or significant curvature (for example, ampoules, small bottles), the label is greatly deformed. If the label material is sufficiently elastic, it will tend to return to a flat shape and the adhesive layer will be subject to high stress. In this case, increased demands are placed on the adhesive and cohesive strength of the adhesive.

It should also be noted that for good adhesion of labels, the surfaces on which they are applied must be cleaned of dust, grease, chemical residues used in the production of the product or packaging, etc.

How the composite “sticks” to the enamel surface

As noted above, in dentistry the mechanisms of adhesion to enamel and dentin differ. The protective outer shell of teeth is transformed by acids. If you examine the enamel after acid etching under a microscope, it will resemble a honeycomb. In this case, the acid works to strengthen the bond with the composite. As a result, viscous hydrophobic adhesives more easily penetrate deeper layers of enamel and provide strong adhesion to the composite.

Interesting! Enamel is considered the hardest tissue in our body. It contains the largest amount of inorganic substances - approximately 97%. The remaining 2% is water, 1% is organic matter.

Influence of label application conditions on adhesion

Depending on climatic conditions, the surface to be labeled may have a temperature different from room temperature and be covered with a layer of moisture, which negatively affects the adhesion of the adhesive. At low temperatures, the adhesive becomes harder, which reduces its adhesive properties, especially the ability to initially set. At elevated temperatures, the glue, on the contrary, softens, which impairs its cohesive strength.

When applying a label to a refrigerated product, moisture may condense on its surface. Since water-based adhesives tend to absorb moisture, their adhesion to wet surfaces may be unsatisfactory.