Foundry plant "DUCATRON"

Since 1968

produces the world-famous

Ducatron

.

A distinctive feature of a modern foundry installation is that it has a built-in thyristor generator with a very high efficiency - 90% of the power consumption, while traditional tube generators have an efficiency of no more than 80%. In addition, the thyristor generator provides stable output power, which ensures the specified melting modes and has a positive effect on the quality of the melted metal.

The optimal operating frequency of the generator (135 kHz) ensures the best mixing of the metal during melting, which guarantees the homogeneity of the alloy and eliminates surface overheating typical of traditional tube generators.

The design of the centrifuge for pouring molten metal into the mold is made in such a way that it ensures automatic balancing of the flask and crucible due to a counterweight installed at the rear of the lever. Equilibrium is achieved by using cylinder-cradle sets of constant weight.

In addition, the centrifuge is equipped with a lever position sensor and has an automatic lift, which is guaranteed to prevent damage to the melting crucible from accidental breakdowns during melting and pouring molten metal into the mold.

Foundry plant "DUCATRON"

has simple control using membrane keys and smooth adjustment of output power, which guarantees high-quality melting of any dental alloys in a wide temperature range.

This installation is also equipped with a lid lock during work associated with melting and pouring metal and, in addition, it is equipped with everything necessary for work, including a set of crucibles for melting both noble and non-precious dental alloys, crucible holding tongs, built-in power control system, protection of the alloy from oxidation by argon, etc.

This process is widely used in prosthetics with fixed (inlay, half-crown, crown, bridge) and removable (arch, with a metal base) prostheses and splints, orthodontic and maxillofacial prostheses and devices.

Casting is the process of producing casts of the required prosthetic parts by pouring molten metal into a mold.

A variety of equipment is used for melting metal alloys: acetylene torches, electric arc units, resistance furnaces and automated high-frequency furnaces, which provide higher quality casting.

Casting of low-melting alloys (with a melting point of up to 300 ° C), intended for creating metal stamps, is carried out using a plaster mold and melting the metal in a special metal spoon over the flame of a gas or alcohol burner.

Casting of hard-melting (medium-melting) metals (with a melting point above 1100 ° C) is carried out to obtain the frame of a dental, jaw or facial prosthesis.

To obtain a high-quality cast prosthesis frame, it is necessary to carefully complete all the stages associated with the preparation of casting, strictly maintain the regime of the casting process itself, and use only factory-made blanks of metal alloys for prostheses. In addition, for each metal alloy it is necessary to use its own ceramic crucible, the strength and chemical resistance of which allow it to be used, as a rule, no more than 6 times.

The process of casting a prosthesis frame from metal alloys includes a number of sequential operations:

1) production of wax reproductions (models) of the prosthesis frame. This process is outlined in Chapters 5 and 6.

2) installation of gating pins and creation of a gating system. For all methods of casting in a mold, in addition to the metal frame form, a gating system is provided, which is channels through which liquid metal is supplied to the casting.

The gating system is created by applying polymer or wax sprue-forming pins to the wax reproduction (model) of the prosthesis frame, which, after removing the wax from the flask, become casting channels. In addition, the gating system allows the formation of the porous structure to be shifted away from the casting objects.

A flask in foundry production is a device made of cast iron, steel or aluminum for holding the molding mass during the manufacture of a casting mold and filling it with metal.

There are certain conditions for constructing a gating system:

— during casting, all areas of the prosthesis frame must be in equal conditions. This is achieved by using ready-made wax rod-profiles and wax wire with a diameter of 2.5; 3.0; 3.5; 4.0; 4.5 mm, or they are modeled directly in the dental laboratory. Moreover, for small parts, one sprue with a diameter of 1.5-2.5 mm is used, for large (thick or extended) ones - 3-6 sprues, with a diameter from 2.5 to 4.5 mm. Moreover, if the prosthesis frame has several metal-intensive sections connected to each other by means of openwork parts, then each such section must have its own sprues. All gates are united by a common large-diameter manifold, which ends in a funnel-shaped expansion;

— the dimensions of the gating system must ensure the process of solidification of the alloy in the sprues later than in the cast prosthesis frame. The length of the sprue should be such that the highest point on the wax model is 6 mm from the edge of the flask ring. If the wax model of the denture frame is too close to the edge of the flask ring, the molten metal may penetrate the molding compound during casting; if it is too far away, the gases cannot escape quickly enough to ensure that the alloy fills the mold cleanly.

On the other hand, a sprue that is too short forces the wax frame of the prosthesis to be placed closer to the upper edge of the flask, which leads to premature cooling of the metal, leading to an increase in the number of casting defects;

- molten metal should flow from thick-walled areas to thinner ones. Therefore, on the sprue, near the massive areas of the wax reproduction (model) of the prosthesis frame, a thickening (coupling) is created - an additional depot of liquid metal to eliminate shrinkage cavities, looseness and porosity in the metal;

— it is necessary to take into account not only the number, length and diameter of the gates, but also their direction and location, since they should not sharply change the direction of the metal flow, and the centrifugal force would contribute to the compaction of the metal;

3) selection and preparation of refractory molding mass, which is a refractory fine powder and binders. Let us recall that, depending on the formulation, metal alloys based on noble and base metals not only have different melting temperatures (gold alloys - up to 1100 ° C; stainless steel - 1200-1600 ° C; cobalt-chromium alloys (CHS) - 1458 °C), but also different amounts of shrinkage during the transition from the liquid to the solid state (for stainless steel it is 1.1-1.25%, for gold-containing alloys - 1.3% of the volume, for KHS - 0.3%).

In modern foundry production, various molding materials are used to compensate for this shrinkage, which determines the choice of molding mass:

— gypsum — for casting prosthetic frames from gold alloys;

— phosphate — for casting prosthetic frames from all types of alloys, including cobalt-chrome;

— silicate — for casting stainless steel frames. During the casting process, it is necessary to ensure the removal from the foundry

forms of air, moisture and gas released from a liquid metal alloy. To do this, the casting mold must be gas-permeable (insufficient gas removal leads to the formation of gas pockets in the casting). In addition, such a mass must be plastic, strong, fire-resistant, and have a coefficient of thermal expansion (CTE) equal to that of the metal alloy used.

Four mechanisms play a role in creating an expanding mold:

a) expansion during hardening of the molding mass, which occurs as a result of normal crystal growth. The expansion likely increases the silica particles in the molding compound, which interfere with the formation of the crystalline structure of the gypsum, causing it to expand outward. This type of expansion under normal conditions is typically about 0.4%, but the expansion is partially limited by the metal ring;

b) hygroscopic expansion. It can be used to increase normal expansion. The molding compound is allowed to harden in the presence of water, causing further expansion. It is assumed that the water into which the molding compound is immersed replaces the water occupied during the hydration process. This holds space between the growing crystals, allowing them to continuously expand outward instead of limiting them. This expansion varies from 1.2 to 2.2% and can be controlled by adding a certain amount of water to the hardening molding compound;

c) expansion of the wax model. Occurs in the liquid molding compound when the wax is heated to the temperature at which it was modeled. Heat can be generated from a chemical reaction in the molding compound or from the water bath in which the ring is immersed. The expansion of the wax model when the mold is in water is less than when the molding mass hardens in air;

d) Thermiges expansion. Expansion of the molding mass occurs when it is heated in a muffle furnace. Heating the mold also helps remove the wax pattern and prevent the alloy from hardening before the mold is completely filled. The method of high-temperature burning of a wax model is primarily based on the thermal expansion of the mold. The molding compound around the wax model is allowed to harden in air at room temperature and then heated to approximately 650°C. At this temperature, the molding compound and metal ring expand enough to compensate for the shrinkage of the gold alloy.

The preparation of the refractory molding mass is carried out in strict accordance with the recommendations of the manufacturer. This concerns, first of all, the volume-weight ratio of the components (powder and liquid of the appropriate concentration), which makes it possible to match the CTE of the refractory material and the metal alloy when casting prosthetic frames.

Mixing the components of the molding mass is carried out manually or in special vacuum mixers (for example, Aveyron, Smartmix, etc.). In this case, as a rule, powder is added to a container with a measured amount of liquid;

4) molding of a wax reproduction (model) of the prosthesis frame and gating system with a refractory mass in a flask is carried out in accordance with the recommendations of the manufacturer. However, some general manipulations should be noted:

- covering the wax reproduction (model) of the prosthesis frame and gating system with a special liquid to improve the fluidity of the molding material and a fire-resistant facing layer, which is applied with a brush or immersed several times in the liquid mass;

— drying the applied facing layer (fireproof shell) at room temperature;

— installation of a wax reproduction of the prosthesis frame lined with molding mass in a flask on the flask cone and its fixation (strengthening) with hot wax;

FLASH CONE - a funnel-shaped hollow device (usually metal or polymer) used to create a reservoir of liquid metal in the flask when casting the metal frame of the prosthesis.

— filling the flask with molding mass (in the required volume) on a vibrating table;

— releasing the flask from the cone after hardening of the molding mass.

5) wax melting, drying and firing of the casting mold (flask) are carried out in special firing (muffle) according to the regime recommended for a given molding (refractory) mass.

Roasting - heating and holding at high temperatures (in kilns) of various materials to give them the necessary properties or remove impurities (for example, roasting ore, clay, refractories, ceramics).

Firing is necessary for the final burning of wax residues, drying, increasing the gas permeability of the mold, as well as creating a high temperature inside the mold and gating channels so that the liquid metal flowing through them does not cool down, for its better fluidity. It is stopped only when the mouths and walls of the casting channels become red. But here the golden mean is good, since overheating of the mold, a rapid increase in temperature in the muffle furnace where firing is carried out, and heating of the mold in an open flame lead to its cracking and shedding. For metals used in dentistry, the optimal firing temperature is from 700 to 850 °C.

The length of time the flask remains in the firing furnace is related to the volume-weight ratio of the components of the molding mass used for the flask: the higher the concentration of the special liquid (i.e., the lower the water content in the flask), the shorter the calcination time of the flask. In addition, the concentration of the special liquid determines the coefficient of thermal expansion of the flask. As an example, we give three modes of calcination in a muffle furnace of a flask made of refractory (molding) mass Power Cash:

1st mode - placing the flask in a hot oven (to quickly burn out the wax) at a temperature of 700-800 ° C, followed by raising the temperature to the final value and exposing (holding) the injection mold in the oven for 40 minutes. This mode, which saves time by at least 80 minutes, is used when casting frames from gold alloys;

2nd mode - placing the flask in a hot peg (to quickly burn out the wax) at a temperature of 430 ° C, followed by raising the temperature to the final value when obtaining prosthetic frames from alloys with a melting point above 1100 ° C;

3rd mode - placing the flask in a cold peg for two-stage calcination. Moreover, in the range from room temperature (22 °C) to 430 °C, its rise rate is 8 °C/min. At a temperature of 430 °C, the investment ring is kept for 30 minutes, and then (after raising the temperature to the maximum value with a heating rate of 14 °C/min) the investment ring is additionally kept in the oven for at least another 30 minutes.

Moreover, when using carbon-phosphate-free molding material Fujivest and Fujivest Super (Japan), used for casting frames from any metal alloy, the flask is placed directly into a heated kiln at a final temperature of 800 ° + 50 ° C, which saves time up to two hours. Such rapid heating of the flask does not affect the expansion and surface quality of the metal alloy.

It should be noted that ceramic crucibles in which metal alloys are melted are placed in a muffle furnace at the same time as the flask, so by the end of this procedure the flask and the ceramic crucible have the same temperature;

6) melting and casting of metal alloy. After carrying out the above preliminary activities, casting is carried out - the process of producing shaped castings by filling pre-prepared forms with liquid metal, in which the metal solidifies.

There are several ways to pour metal into molds:

- free filling - metal fills the mold freely, under the influence of gravitational forces;

— casting under pressure created by a piston or air using casting machines;

- centrifugal casting - pouring into a rotating mold - metal fills it under the influence of centrifugal and gravitational forces;

— vacuum casting — filling with vacuum suction.

When casting, some overheating of the metal is allowed, but not higher than the melting point by 100-150 ° C. A further increase in heating leads to significant absorption of gases and the subsequent formation of gas shells.

Obtaining a high-quality casting of the prosthesis frame depends on the temperature of the melt. So, if the melt temperature is insufficient:

— premature hardening occurs, which affects the quality of the casting structure;

— there is a risk of premature clots forming. Conditions for the formation of clots arise when the heating temperature is insufficient, which does not allow the metal flows to completely mix;

— low casting temperature with a large casting area leads to a wavy structure of its surface;

— when the alloy is not heated sufficiently, premature hardening of the metal occurs, which is manifested by underfilling of casting objects;

— ripples on the surface are explained by low casting temperatures. Due to rapid solidification, the ripples that appear due to the presence of oxide films on the metal surface do not disappear.

If the melt temperature is excessive or the heating time of the investment ring increases, it is possible:

— destruction of the molding mass. The instability of the structure of the molding mass upon contact with the flowing molten metal leads to the release of microscopic particles of the molding material, which enter the surface parts of the casting. Significant factors in the reaction between the alloy and the mold material are: the temperature of the metal (any alloy with a casting temperature above 1150 ° C, which exceeds the melting point by 38-66 ° C, must be cast in a phosphate molding compound), its chemical composition, surface tension , metal statics, mold composition, as well as thermal, chemical and mechanical stability of the molding mass;

- evaporation of alloy components (for example, zinc) and the development of decomposition reactions of the molten metal with the formation of gases that interfere with filling the casting mold. This effect occurs when a high-temperature alloy is used in combination with gypsum-based molding compounds. Gases are released during the cooling and solidification of the metal, since their solubility decreases with decreasing temperature, although during the cooling process most of the gases may leave the metal, but the remaining gases form pores in the structure of the casting;

— the occurrence of a sponge effect, when during the solidification of the alloy in the cavity, the gas rises to the surface of the molten metal, but due to the dense structure of the molding mass, it is not able to go beyond the casting. At the same time, a process of uncontrolled solidification of the overheated alloy occurs, which leads to the formation of a porous structure of the casting;

— the occurrence of heterogeneity in the casting structure;

— an increase in shrinkage in the casting, which manifests itself in an increase in the rigidity of the prosthesis frame.

During the transition from liquid to solid, the molten metal decreases in volume. Lack of volume during the casting process is expressed as compression porosity, which can be found primarily in areas where the metal is the last to solidify;

7) freeing the prosthesis frame from the refractory mass and gating system. After removing the flask from the foundry installation, it is cooled, and, in order to prevent internal stress and cracks, it is recommended to cool the castings slowly: in air or in a heated but switched-off muffle furnace.

Then carefully remove with a plaster knife or squeeze out the molding mass from the flask:

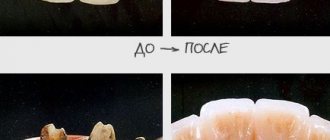

— a casting of gold alloys is heated by a soldering apparatus and lowered into a solution of hydrochloric acid. The sprues are then cut using a carborundum or vulcanite disc. The casting is processed with carbide burs and carborundum stones of various styles until a smooth surface is obtained;

- when the facing mass is tightly baked to the surface of a metal casting made of base metal alloys, the latter are immersed in an acid or alkali solution. More often, ultrasonic cleaning or treatment in a sandblasting chamber is carried out.

The gating system is separated from the prosthesis frame using cutting wheels and discs.

The option discussed above for obtaining a cast frame (or its element) of a denture is an intermediate step in the process of creating a denture.

It should be noted that the release of the prosthesis frame from the refractory mass and gating system, as well as its finishing, is essentially a combination of mechanical, thermomechanical and chemical processing of metal alloys, which requires these manipulations to be carried out in specially equipped production facilities with strict adherence to technological discipline and safety precautions and operating conditions of the equipment, mechanisms and devices used for this purpose, recommended by the manufacturer.

Foundry plant "INDUCAST"

Vacuum melting

Based on our many years of experience and modern technologies,

introduced the vacuum casting machine

"INDUCAST"

. The vacuum melting concept offers many advantages: dental alloys are melted in a vacuum (or inert gas environment) and the alloy is poured into the mold under pressure. The optimal operating frequency of the generator (135 kHz) ensures heating of all types of dental alloys in a wide temperature range and guarantees the production of high-precision dental castings with high surface cleanliness.

A characteristic feature of the foundry installation "INDUCAST"

also is that evacuation, heating of the molten metal and subsequent casting of the molten metal into a mold under pressure occurs in one chamber.

- Therefore, compared to other types of high-frequency casting installations, all this provides significant advantages, namely:

- The inability to overheat the molten alloy makes it possible to obtain both high precision and high quality dental casting.

- The ability to create a vacuum in the melting chamber of this installation eliminates the waste of alloying elements of the alloy, the formation of chemical vapors from the refractory mixture and thereby ensures high cleanliness of the surface of the dental casting.

- The use of argon to ensure that the molten alloy is poured under pressure into the mold prevents oxidation of the alloy.

In the "INDUCAST"

There is a built-in closed circuit for cooling the inductor and a vacuum pump to ensure the creation of a vacuum in the melting chamber. The top cover of the casting machine has a simple and reliable safety mechanism for its closure, it is equipped with a closure detector, and also has an observation window for direct observation of the alloy as it is melted and cast into the mold.

As the exclusive representative of Ugin Dentaire in Russia, Stomatorg LLC provides warranty (for 2 years) and post-warranty service for foundry installations.